Join the MF IDEAL revolution

It’s a satisfying moment when you look out onto ripened crops and know that you are ready to go with the harvest. Then it’s all down to you and your combine to turn all those months of work into a profitable income.

Designed for large-scale arable operations and contractors the MF IDEAL is fully connected, with unique new features, excelling in every area and offering superb grain and straw quality, massive output, super-fast operation, outstanding driver comfort, plus total efficiency and control.

Now the optional MF IDEALdrive provides even more comfort and greater working efficiency. The conventional steering wheel is replaced by the IdealDrive steering joystick, for effortless manoeuvrability, quick headland turns and an unobstructed view of the header.

Key Benefits

Technology & Innovation

POWERFLOW

PowerFlow™ is a table offering high capacity in all conditions. Belts transport the crop straight from the knife to the table auger ensuring seamless feeding.

TERRACONTROL II

TerraControl II provides a mix of automatic functions for the standard table-levelling, ground-following (Field pressure) and headland management systems – everything is controlled from the operator’s PowerGrip lever.

AutoDock Option

When hooking-up the header from a header trailer or from the ground, the operator simply presses a button in the cab and all the connections - mechanical, electrical and hydraulic - are made automatically by a robotised process.

IDEAL DriveCenter

One gearbox, attached directly to the engine, drives all main components of the combine: the processor, cleaning system and hydraulic pumps, as well as the header, including today’s newest corn chopper heads.

MF IDEAL Engines

The IDEAL is available in three models with power and capacity to suit different requirements of producers and operators. IDEAL 7: AGCO Power, 9.8 L / 483 HP | IDEAL 8: MAN 12.4L/ 549 HP | IDEAL 9: MAN 15.2L/ 660 HP

Fewer Belts and Wet Clutches

Because belts can siphon off power via slippage and breakage, the IDEAL uses fewer of them than other combines. Wet clutches on the DriveCenter also ensure smooth engagement, thereby reducing wear and tear—and maintenance—on each component.

AIRSENSE COOLING

AirSense cooling provides an optimal ventilation of the MF IDEAL engine, even in the dustiest conditions. A reversing fan prevents dust and chaff accumulations, and almost completely removes the need for manual cleaning during the harvest.

Exceptional Cab Visibility

Narrow pillars in the cab offer a fantastic panoramic view with excellent all-round visibility through a massive glass area of 5.75m². Many of the operator tasks now have short-cuts to make the machine easier to operate.

Visibility Options

LED lights, single rear-view, multiple or 3D camera options improve visibility for long hours working.

Optional Pro Sound System

A higher specification Pro Sound system can be supplied as an option.

MF IDEALDRIVE

It offers an unprecedented level of machine control and an even clearer view of the header. A joystick on the left armrest replaces the conventional steering wheel, while the PowerGrip lever on the right varies the speed and direction.

HOMOLOGATED FOR EU ROAD TRAVEL

An option on TrakRide models, and fully homologated for EU road use, the IDEALdrive joystick increases productivity by 6% compared to conventional steering systems, while the operator workload is reduced by 65%.* *study conducted at Aalborg University.

ARMREST AND CONTROLS

The right-hand PowerGrip armrest houses the main controls including the PowerGrip multifunction joystick. On a new adjustable mounting arm, the TechTouch Terminal displays performance information and allows adjustments to be made from the seat.

UNLOADING RATE ADJUSTMENT FROM THE CAB

Select the best unloading rate for the crop and conditions. Quick and convenient adjustment through the PowerGrip lever – even when the tank is full or during unloading. Optimise trailer filling with reduced risk of grain spillages.

Streamer 140

MF IDEAL also offers the Streamer 140, which unloads the 12,500-litre grain tank at 140 L/sec. It is standard on the MF IDEAL 7 and 8, and all ParaLevel models.

Streamer 210

Standard on the MF IDEAL 9 and an option on MF IDEAL 7 and 8, the 17,100-litre grain tank unloads at up to 210 L/sec – the fastest in the industry. New auger lengths compatible with controlled traffic farming operations are available.

Dual Helix Rotors

The 4.8m long Dual Helix processor with 600 mm diameter of the rotors generates huge centrifugal forces for thorough but gentle crop separation. Dual Helix on IDEAL 8 and IDEAL 9 provide a 1.66m2 concave area – one of the industry’s largest.

Grain Handling

On all models, unloading speed and grain tank capacity are coupled with an innovative auger that is gentle on grain, ensuring less damage, and it requires less power than older systems.

Dual Helix Processor

Compared to other systems, the Dual Helix processor requires less power to operate in a range of crop conditions. The synchronised rotor feeder speed optimises crop flow and, while the rotor is exceptionally efficient, its performance is best-in-class.

IDEALBALANCE™ GRAIN-PAN SYSTEM

With no extra moving parts, the specially-shaped under-rotor pans allow full cleaning performance to be maintained even on slopes up to 15%. The grain mix is placed in the right position so that the entire length and area is available for cleaning.

TrakRide

The TrakRide system ensures exceptional performance and comfort, while reducing maintenance and enhancing reliability, all of which help ensure the combine is up and running at full capacity in short harvest windows.

TrakRide Belt Sizes

TrakRide rubber tracks ensure exceptional performance and comfort, and achieve a large footprint to reduce soil compaction. Track widths of 26”, 30” and 36” are available, and the unique suspension system also maintains the correct belt tension.

CHAFF SPREADER

Flexible residue handling comes standard with all MF IDEAL models, allowing optimum strategies for straw and chaff handling to suit any crop and situation.

THREE DIFFERENT SPREADING DIRECTIONS

Chop and mix chaff and straw together in the chopper, and spread across the full cutting width. Chaff distributed across the straw swath to maximise straw quantity and quality. Spread chaff to the sides, away from swathed or chopped straw.

PARALEVEL

For farm operations with a higher proportion of slopes, a ParaLevel version of each model is available. These use a special axle arrangement to keep the whole machine level at angles up to 14%.

CYCLONE PLUS CLEANING SYSTEM

The high capacity cleaning system with adjustable pre-sieve and double cascade ensures earlier grain separation and increased ventilated area. The optimised air flow ensures consistent, clean sample and easy set up in a wide range of crops.

ACTIVESPREAD SWINGFLOW

Achieve even residue distribution in all crops and conditions. Hydraulic driven spinners with swinging deflectors create a homogeneous spread pattern across the full cut width – even on windy days. The efficient design saves power and fuel.

NARROW WIDTH WITH LARGE FOOTPRINT

The IDEAL TrakRide rubber track system protects soils and extends working windows, while the narrow transport width and 40kph maximum speed makes the combine easier to move between work areas on the road.

Mass Acoustic Detection Systems - MADS

Measuring the differences in acoustic qualities, the sensors can determine what is grain and what is not and direct the IDEALharvest system to change the necessary combine settings–all to maintain the operator’s harvest strategy.

IDEALharvest Touch Screen Tablet

Real time visualisation enhances control. The harvest strategy itself is set by an easy-to-use touch-screen tablet, allowing the operator to select preferences for minimizing grain damage, loss and material other than grain (MOG) in the bin.

IDEALharvest

The IDEALharvest system offers unprecedented, real-time visualisation of crop flow within the combine via a special grain-quality camera and numerous sensors, including mass acoustic detection sensors (MADS).

MF GUIDE

MF Guide is MF’s full featured, hands-free steering system. It is capable of delivering sub-metre, decimetre and centimetre accuracy, increasing the efficiency of your farm.

MF TASK DOC

The MF Task Doc system helps improve productivity by putting precision-measured data at the business owner’s fingertips. Live yield mapping is standard – providing a real time view of the harvested yield while the task is in progress.

MF CONNECT

MF Connect enables you — and your dealer — to coordinate, optimise and seamlessly connect your fleet, to easily manage maintenance and remotely monitor equipment in the field.

Available Models

Model |

Max Power (hp) |

Grain Capacity (l) |

Unloading speed (l/s) |

Max cutting width (m) |

Engine |

|---|---|---|---|---|---|

| IDEAL 7 | 483 | 17,100 | 210 | 10.7 | AGCO Power 9.8 L |

| IDEAL 8 | 549 | 17,100 | 210 | 12.2 | MAN 12.4 L |

| IDEAL 9 | 660 | 17,100 | 210 | 12.2 | MAN 15.2 L |

Customer Reviews & Testimonials

Crowmarsh Battle Farms

An Oxfordshire farming family which replaced two combines with one larger Massey Ferguson IDEAL 9PL remains delighted with the decision after the combine completed its third harvest this year.

Nowak Family

Investing in a Massey Ferguson IDEAL 7 combine has enabled a German farming family to increase productivity while achieving an excellent grain sample and great straw quality.

Miklós Cicárdi

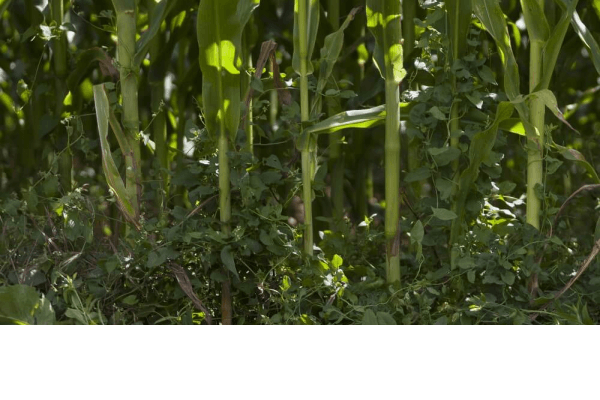

Large-scale farmer Miklós Cicárdi runs Gazdakör Kft. Company with his family in Pellérd, southern Hungary. The farm extends over 1,800 hectares, where he grows barley, wheat, corn, sunflower, rapeseed and soybean.

Mark Trotter

A Massey Ferguson Ideal 8T combine, selected following on-farm demonstrations of the new model plus several competitors, achieved all that was expected of it and more during its first harvest on a North Lincolnshire farm.

Rauceby Farms

A Lincolnshire farm which previously struggled to achieve satisfactory harvesting speeds without incurring high grain losses, changed to a Massey Ferguson Ideal 7 combine for the 2020 harvest and is very happy with the result.

-moscrop-ideal-1220/MF_Moscrop_ideal_1220_1400x700.jpg)

C&R Moscrop & Sons

It performed exceptionally well - that’s the verdict of a West Yorkshire-based farmer and contractor after his first harvest with a new Massey Ferguson Ideal 7 PL combine.

Share