Tractors

MF 9S

MF 9S

Outstanding Design, Ultimate Performance

MF 8700 S

MF 8700 S

The new touch of high horsepower & precision farming

MF 8S Xtra

MF 8S Xtra

Designed by Farmers for Farmers

MF 8S

MF 8S

Straightforward & Dependable

MF 7S

MF 7S

A Superior Farming Experience

MF 7700 S

MF 7700 S

Born to Farm

MF 6S

MF 6S

Concentrated Performance

MF 6700 S

MF 6700 S

A Pure Concentration of Power

MF 5S

MF 5S

The best-in-class dairy and livestock tractor

MF 5M

MF 5M

Affordable efficiency

MF 5M

MF 5M

Affordable efficiency

MF 5700 M

MF 5700 M

Straightforward efficiency

MF 400 Xtra

MF 400 Xtra

Rugged & Dependable

MF 4700 M

MF 4700 M

Straightforward efficiency

MF 3

MF 3

Specialists like you!

MF 300 Xtra

MF 300 Xtra

Total Support for you and your farm

MF 200 Xtra

MF 200 Xtra

Simple, Powerful, Reliable

MF 1700 M

MF 1700 M

Your New Best Compact Partner

MF 1700 E

MF 1700 E

Compact, affordable performance

MF 35

MF 35

The people's tractor

MF 1M

MF 1M

Reliable Performance in a Compact Design

Combine Harvesters

MF IDEAL

MF IDEAL

The Harvest Game Changer

MF Beta AL4

MF Beta AL4

Where it is needed

MF Beta

MF Beta

This is where it matters

MF Activa S

MF Activa S

Flexibility is the key

MF Activa

MF Activa

Unchallenged Versatility

Balers

MF SB 1840

MF SB 1840

Straightforward Baling

MF SB 1842S

MF SB 1842S

High capacity small square baler

MF LB 2200

MF LB 2200

Outstanding Performance

MF RB F

MF RB F

High output and cost effective

MF RB F PROTEC

MF RB F PROTEC

Non-stop excellence

MF RB V

MF RB V

High output and cost effective

MF RB V PROTEC

MF RB V PROTEC

Non-stop excellence

Hay and Forage

MF RK Series

MF RK Series

High Performance Range of Rakes

MF DM & M Series

MF DM & M Series

Innovative and Efficient Mowers & Mower Conditioners

MF TD Series

MF TD Series

Latest Generation of High Output Tedders

Materials Handling

MF TH

MF TH

A New Era of Comfort and Productivity

MF FL

MF FL

Hard working, high performance loaders

MF FL X

MF FL X

When time’s not on your side, we are.

Planters

MF 100

MF 100

No-Till Planters

MF 200

MF 200

Mechanical Planter

MF 300

MF 300

Trailed Grain and Rice Drill

MF 400

MF 400

Mechanical Planter

MF 500

MF 500

Trailed Mechanical or Vacuum Meter Planter

MF 700

MF 700

Trailed Pneumatic Planter

Livestock

Materials Handling

MF TH

MF TH

A New Era of Comfort and Productivity

MF TH

MF FL

MF FL

Hard working, high performance loaders

MF FL X

MF FL X

When time’s not on your side, we are.

Balers

MF SB 1840

MF SB 1840

Straightforward Baling

MF SB 1842S

MF SB 1842S

High capacity small square baler

MF LB 2200

MF LB 2200

Outstanding Performance

MF RB F

MF RB F

High output and cost effective

MF RB F PROTEC

MF RB F PROTEC

Non-stop excellence

MF RB V

MF RB V

High output and cost effective

MF RB V PROTEC

MF RB V PROTEC

Non-stop excellence

MF TW

Tractors

MF 6700 S

MF 6700 S

A Pure Concentration of Power

MF 5S

MF 5S

The best-in-class dairy and livestock tractor

MF 5700 M

MF 5700 M

Straightforward efficiency

MF 400 Xtra

MF 400 Xtra

Rugged & Dependable

MF 4700 M

MF 4700 M

Straightforward efficiency

MF 3700 AL

MF 3700

MF 300 Xtra

MF 300 Xtra

Total Support for you and your farm

MF 200 Xtra

MF 200 Xtra

Simple, Powerful, Reliable

MF 1700 M

MF 1700 M

Your New Best Compact Partner

MF 1M

MF 1M

Reliable Performance in a Compact Design

MF 35

MF 35

The people's tractor

Hay and Forage

MF DM & M Series

MF DM & M Series

Innovative and Efficient Mowers & Mower Conditioners

MF TD Series

MF TD Series

Latest Generation of High Output Tedders

MF RK Series

MF RK Series

High Performance Range of Rakes

Arable

Materials Handling

Balers

MF SB 1842S

MF SB 1842S

High capacity small square baler

MF LB 2200

MF LB 2200

Outstanding Performance

Planters

MF 100

MF 100

No-Till Planters

MF 200

MF 200

Mechanical Planter

MF 300

MF 300

Trailed Grain and Rice Drill

MF 400

MF 400

Mechanical Planter

MF 500

MF 500

Trailed Mechanical or Vacuum Meter Planter

MF 700

MF 700

Trailed Pneumatic Planter

Tractors

MF 9S

MF 9S

Outstanding Design, Ultimate Performance

MF 8700 S

MF 8700 S

The new touch of high horsepower & precision farming

MF 8S Xtra

MF 8S Xtra

Designed by Farmers for Farmers

MF 8S

MF 8S

Straightforward & Dependable

MF 7700 S

MF 7700 S

Born to Farm

MF 6700 S

MF 6700 S

A Pure Concentration of Power

MF 5S

MF 5S

The best-in-class dairy and livestock tractor

MF 5700 M

MF 5700 M

Straightforward efficiency

MF 4700 M

MF 4700 M

Straightforward efficiency

Combine Harvesters

MF IDEAL

MF IDEAL

The Harvest Game Changer

MF Beta

MF Beta

This is where it matters

MF Activa S

MF Activa S

Flexibility is the key

MF Activa

MF Activa

Unchallenged Versatility

Hay and Forage

MF RK Series

MF RK Series

High Performance Range of Rakes

Vineyards & Fruit

Tractors

MF 4700 M

MF 4700 M

Straightforward efficiency

MF 3700 AL

MF 3700

MF 1700 M

MF 1700 M

Your New Best Compact Partner

Hay and Forage

MF DM & M Series

MF DM & M Series

Innovative and Efficient Mowers & Mower Conditioners

Mixed

Materials Handling

MF TH

MF TH

A New Era of Comfort and Productivity

MF TH

MF FL

MF FL

Hard working, high performance loaders

MF FL X

MF FL X

When time’s not on your side, we are.

Balers

MF SB 1840

MF SB 1840

Straightforward Baling

MF LB 2200

MF LB 2200

Outstanding Performance

MF RB F

MF RB F

High output and cost effective

MF RB F PROTEC

MF RB F PROTEC

Non-stop excellence

MF RB V

MF RB V

High output and cost effective

MF RB V PROTEC

MF RB V PROTEC

Non-stop excellence

MF TW

Planters

MF 100

MF 100

No-Till Planters

MF 200

MF 200

Mechanical Planter

MF 300

MF 300

Trailed Grain and Rice Drill

MF 400

MF 400

Mechanical Planter

MF 500

MF 500

Trailed Mechanical or Vacuum Meter Planter

MF 700

MF 700

Trailed Pneumatic Planter

Tractors

MF 9S

MF 9S

Outstanding Design, Ultimate Performance

MF 8700 S

MF 8700 S

The new touch of high horsepower & precision farming

MF 8S Xtra

MF 8S Xtra

Designed by Farmers for Farmers

MF 8S

MF 8S

Straightforward & Dependable

MF 7700 S

MF 7700 S

Born to Farm

MF 6700 S

MF 6700 S

A Pure Concentration of Power

MF 5S

MF 5S

The best-in-class dairy and livestock tractor

MF 5700 M

MF 5700 M

Straightforward efficiency

MF 400 Xtra

MF 400 Xtra

Rugged & Dependable

MF 4700 M

MF 4700 M

Straightforward efficiency

MF 3700 AL

MF 3700

MF 200 Xtra

MF 200 Xtra

Simple, Powerful, Reliable

MF 1700 M

MF 1700 M

Your New Best Compact Partner

MF 35

MF 35

The people's tractor

Combine Harvesters

MF Beta

MF Beta

This is where it matters

MF Activa S

MF Activa S

Flexibility is the key

MF Activa

MF Activa

Unchallenged Versatility

Hay and Forage

MF DM & M Series

MF DM & M Series

Innovative and Efficient Mowers & Mower Conditioners

MF TD Series

MF TD Series

Latest Generation of High Output Tedders

MF RK Series

MF RK Series

High Performance Range of Rakes

MF Beta AL4

The MF Beta AL4 combine offers a straightforward, practical design with a mix of technology and functional features that are simple to work with in the field where time is of the essence.

The differential of this model MF BETA AL4 lies in the integral leveling system driven by 4 hydraulic cylinders that allow the adjustment of the machine on slopes, up to 38% transversal, 35% on uphill and 8% on downhill.

Key Benefits

Levelling system

This system offers levelling with the table on slopes up to 38% on traversal, 35% on uphill and 8% on downhill. Combine components are generally designed to work on the level. This system maintains that level longer on slopes, keeping the machine working at maximum efficiency for longer - increasing your output.

MAKE THE MOST OF YOUR WORKING DAY IN THE SKYLINE CAB

A good cab environment is the key to getting the best performance from the machine and operator. The Skyline cab offers excellent visibility of the header, stubble, unloader and at the rear through large electrically adjustable mirrors or the standard camera feature in the Tech Touch Terminal.

Threshing and Separation

The flexible Heart of the Combine. Equipped with a robust, high-inertia cylinder and a heavy-duty concave, these machines can handle crops easily.

XL Grain Tank

The Grain Tanks have a high capacity of 8600 Litres while the Unloading Rate of 105 l/sec is one of the highest in the class.

How much importance do you place on your combine engine?

We can promise you that your AGCO POWER engine has been designed to match the latest emission regulations using third generation SCR technology, meaning that it actually has one of the most advanced designs on the market.

Technology & Innovation

FREEFLOW

With cutting widths from 5.4 m – 7.0 m, the Freeflow™ table features a welded frame to which bolt-on panels (such as the table bottom plates) are mounted, making it extremely easy to replace parts when necessary.

PowerFlow

PowerFlow™ is the industry benchmark table for high capacity in all conditions. The proven belt drive powers the crop into the combine ensuring seamless feeding.

POWER FEED ROLLER

The Power Feed Roller at the front of the main crop elevator gives a consistent crop flow from the table into the main crop elevator. It can be reversed simply and effectively from the cab.

FULL WIDTH AUGER FINGERS

Full width auger fingers on the Freeflow™ table increase auger throughout, ensuring positive and fast feed into the main crop elevator.

POWERFLOW KNIFE

The knife is a massive 1.14m from the table auger so vision and performance are optimum. The rugged PowerFlow belts power the crop away from the knife and into the main crop elevator at a consistent speed.

SCHUMACHER KNIFE - FREEFLOW TABLE

The Schumacher knife is the best performing knife in the business at 1,220 cuts a minute. Self-cleaning and consistently sharp, this keeps the crop moving in tough conditions.

TERRACONTROL II

TerraControl II provides a mix of automatic functions for the standard table-levelling (FreeFlow™ or PowerFlow™), ground-following system (Field pressure) and headland management – all the metrics are controlled from the operator’s multifunction lever.

MULTICROP SEPARATOR - MCS

The MCS provides a massive separation area to remove as much grain as possible before it reaches the walkers. The MCS has the ability to rotate the concave over the top of the rotary separator when it is not required.

8600 LITRE GRAIN TANK

The Grain Tank has a high capacity of 8600 Litres while the Unloading Rate of 105 l/sec is one of the highest in the class.

Up to 6-row straw chopper

Adjustable chopper, with serrated blades creates an excellent chop quality at a low power requirement, providing an even spread of material across the entire working width of the table.

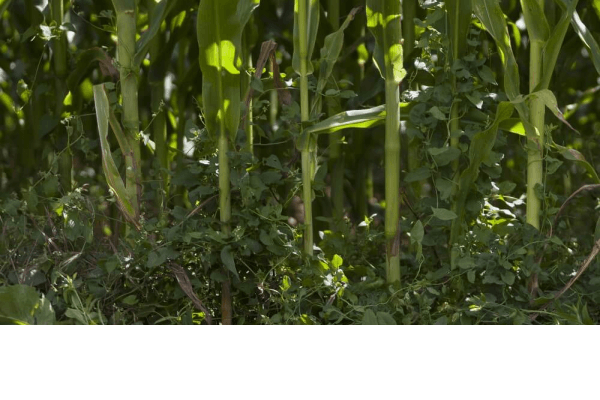

A MULTITUDE OF APPLICATIONS

A full maize kit can be fitted including a maize concave. For this application the chopper speed reduction kit comes as standard with the grain version.

STRAW WALKER

The long straw walkers feature four steps with ‘active walls’. The 210 mm high, vertical sections of the walker steps are made up of permeable grids. These are the highest for any conventional combine.

THRESHING DRUM

For those that require straw, the threshing system is gentle and leaves the straw in perfect condition for baling feed and bedding straw or producing products for power generation.

CONCAVE

The concave has differentiated wire spacing, the rear section of the concave has half as many wires as the front section. This principle provides the optimum balance between high threshing capacity and good grain flow through the concave.

Levelling system

This system offers levelling with the table on slopes up to 38% on traversal, 35% on uphill and 8% on downhill, keeping the machine working at maximum efficiency for longer - increasing your output.

4WD dual displacement system

Part of the package for balance is a standard 4WD dual displacement system, which uses minimum power when climbing small or moderate hills, and maximum power when climbing steep hills.

The Skyline Cab

The Skyline cab offers excellent visibility of the header, stubble, unloader and at the rear through large electrically adjustable mirrors or the standard camera feature in the Tech Touch Terminal.

TECHTOUCH TERMINAL

Perfectly in view and reach is the TechTouch terminal, providing all the relevant performance information and settings for the combine, touch screen controls with clear definition are easy to use and adjust.

POWERGRIP ARMREST

The right-hand armrest is the central operating unit where the key engagement switches sit with the throttle control. Designed with a large soft pad to cushion the arm during a long day allows for maximum comfort.

NIGHT WORKING PACKAGE

Night working package includes H9 high intensity lights for all-round excellent visibility late into the evening.

KEYPAD

The soft touch keypad, located directly to the right side of the armrest, is used to operate the commonly used combine functions. The soft, raised keys lead directly to the individual menus on the TechTouch Terminal.

POWERGRIP LEVER

PowerGrip Multifunction lever falls naturally to hand. Sitting on top of the armrest it contains all the switches for the commonly used controls.

AGCO Power Engine

We can promise you that your AGCO POWER Stage V engines use Selective Catalytic Reduction and Soot Catalyst as the main exhaust after treatment technology.

Engine Performance

Consistent, reliable harvesting performance in all conditions is ensured thanks to the engine delivering a long, flat torque curve specifically designed for constant power delivery under load.

EASY REFUELING

Easy refueling - both tanks are located next to each other for easy access.

EASY INSPECTION

Ladder rail makes inspection easy and safe.

ONE-PIECE PANELS

One piece panels with lights allow for quick inspection access with lights for night work.

RADIATOR CLEANING

Safe and simple access for radiator cleaning.

Available Models

Model |

Max Power (hp/kW) |

Grain Capacity (l) |

Unloading speed (l/s) |

Max cutting |

Engine |

|---|---|---|---|---|---|

| MF Beta AL4 7360 | 306/225* | 8,600 | 105 | 7 | AGCO Power 7.4L, 6-Cylinder, All-in-One Stage V |

| *with Power Boost | |||||

MF BETA AL4 | Combine Harvesters | Overview

Products & Services to compliment your MF BETA AL4

Available service packages

A little extra care goes a long way – fields and fields further.

-

AGCO Support

ExploreWhen you invest in a Massey Ferguson machine you are backed by AGCO, the world’s largest agricultural machinery company.

-

Dealer Support

ExploreProtect your investment in Massey Ferguson and put your machine in the hands of the experts.

-

MF Always Running

Explore‘MF Always Running, Your Courtesy Fleet’ provides a temporary replacement machine to ensure owners can continue working with minimum interruption to maximise uptime while their tractors are being serviced or repaired.

-

MF Care

ExploreMF Care is a way for you to fix your costs at point of purchasing your Massey Ferguson machine, ensure optimum performance and guarantee efficiency and maximise the residual value of your machine. Our MF Care service solutions can be personalised to suit

-

Servicing Options

ExploreProtect your investment in Massey Ferguson with an industry leading service and warranty contract.

-

Technical Literature

ExploreAGCO’s RMI website provides independent operators with access to AGCO’s Repair and Maintenance Information.

Related products & equipment

Approach the task at hand with the right tool for the right job.

-

MF Activa S

Flexibility is the key

ExploreDesigned to offer choice for farmers, the new Massey Ferguson Activa S combine range has features for performance and practicality. The operator has been given new higher levels of comfort in this class while offering simple straightforward choices of specification.

-

MF Activa

Unchallenged Versatility

ExploreThe new MF Activa series provides a choice of high output combine harvesters for farmers who are looking for straightforward and dependable harvesting performance with low running costs.

-

MF Beta

This is where it matters

ExploreThe MF Beta combine harvesters offer a straightforward, practical design with a mix of technology and functional features that are simple to work with in the field, where time is of the essence.

-

MF IDEAL

The Harvest Game Changer

ExploreThe Ideal harnesses industry leading technology to deliver more grain at the best quality, for you. It’s the first “clean-sheet” design of a combine in 30 years—a machine based not on what has come before, but on what producers like you have told us they need, and what we’ve tested in some of the most rigorous trials ever initiated by a farm equipment manufacturer.

Parts Packages

Customised to your need, repaired at your speed.

-

10+

ExploreAs part of AGCO’s promise of a lifetime of support for your Massey Ferguson machinery, we have developed a highly competitive range of original or Massey Ferguson Engineering approved parts for older MF machinery.

-

AGCO Reman

ExploreAGCO Reman is the name for our range of remanufactured products. This is a systematic process where previously used parts are recovered and sent to a remanufacturing centre of excellence and brought back to as new condition.

-

Complementary Products

ExploreYour Massey Ferguson dealer has a huge range of Complementary Products which makes them a one-stop shop for all your farming needs.

-

Dealer Fit Accessories

ExploreGenuine Massey Ferguson accessories offer the same high levels of durability and performance expected of the Massey Ferguson machine.

-

Genuine AGCO Parts

ExploreAGCO Parts are the only genuine and original replacement parts for Massey Ferguson.

-

Parts Books

ExploreOur AGCO Parts Books, available on web and mobile, provides you with access to an electronic catalog where you can easily find replacement part information for your Massey Ferguson machine at any time.

Select your market

Globally welcome, locally specialised. Choose your market below or go straight to our International-English site.

Find a Dealer

No Results found

An unexpected error occurred.

Google maps requires cookies enabled to work correctly.

Share