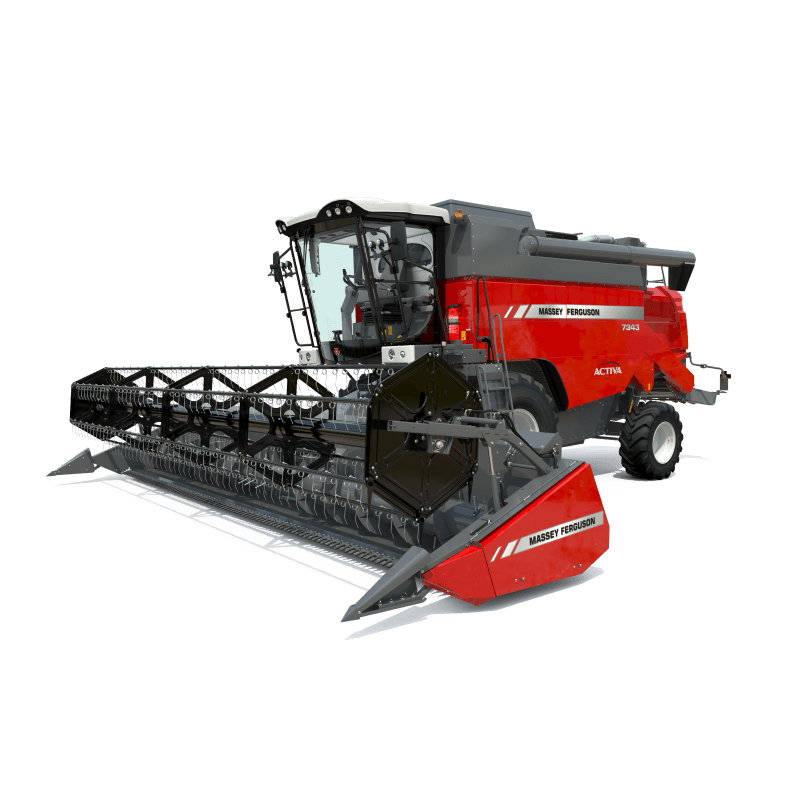

MF 2370 Ultra HD

Advanced, superior design and uncompromising engineering ensure professional contractors and large scale arable farmers can depend on the MF 2370 Ultra HD to deliver perfectly formed, Ultra dense bales all day, every day.

Massey Ferguson large square balers, built in Hesston, are the undisputed industry benchmark, chosen by professionals across the world for their reliability, durability and low cost of ownership.

Key Benefits

Technology & Innovation

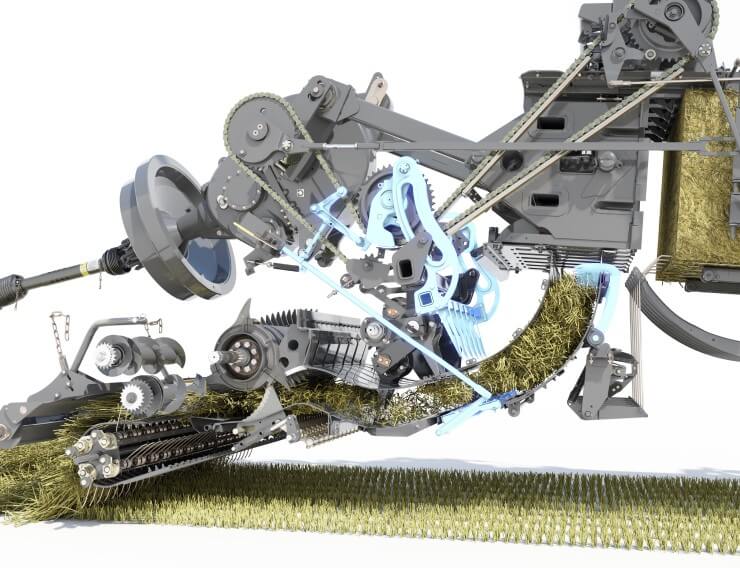

Pre-Compression Chamber

Massive capacity, industry leading bale density and superb shape all stem from the award-winning pre-compression chamber design.

Curved Tip Double Tines

Optimum feeding performance is provided by 80 curved tip double tines, on five tine bars that carefully lift more crop, particularly shorter, delicate material.

OptiFlow Pick-Up Design

Developed specifically to present an even, continuous feed of material to match the baler’s enormous appetite, the OptiFlow Pickup also offers outstanding flotation and ground following thanks to its innovative design.

High Performance Flywheel

A step-up gearbox rotates a new, high performance flywheel at 1,500rpm – which is 50% faster than on the MF 2200 Series. This generates 130% more energy than the XD flywheel to maintain consistent speed for bale quality and smooth, efficient operation.

Polypropylene Wrapper Bands

By pivoting around the lower auger, there’s less to lift. Durable polypropylene wrapper bands further lighten the load, reduce noise and are quick and easy to replace.

UltraPress Plunger

It takes an industry-leading, extreme plunger force of up to 760kN to make Ultra Density, 20% heavier bales. As well as boosting bale weight and density, a significant, 6.5% plunger speed increase to 50 strokes/min also enhances capacity and performance.

Ultra Gearbox

It takes intelligent design and exceptional engineering to boost bale density to efficiently pack 20% more material into the same 120cm x 90cm bale size. MF has developed a new, immensely strong Ultra Gearbox to create this outstanding density capability.

OptiFlow Pick-Up

With 20% greater feeding capacity, the leading-edge OptiFlow Pick-up ensures the MF 2370 Ultra HD baler consistently delivers maximum output.

OptiForm Ultra Bale Density

OptiForm Ultra delivers the density. To handle the enormous capacity the 4.0m long chamber is 20% longer than the MF 2270 XD model.

OptiForm Ultra Density Ring

Huge 178mm diameter density rams – 55% larger than ever before – exert extreme loads to the sides and top of the bale to generate a maximum 760kN plunger force.

OptiForm Ultra Bale Chamber

It takes supreme design, strength and unparalleled Hesston engineering expertise to create a bale chamber tough and reliable enough to make Ultra density bales day in, day out over long, demanding seasons.

EasyFill Twine Boxes

Exclusive EasyFill twine boxes hold a total of 36 super-sized spools of twine in two rows of nine - plenty for the longest day’s work. Six knotters use less twine, which cuts costs and reduces downtime from refilling.

EasyFill Loading

EasyFill boxes are effortlessly loaded from the ground, with no complex lowering mechanism. Twine spools are stored at a slight angle, which makes them easier to slide in place and tie together.

High Capacity Packer Fork

The high capacity packer fork begins the process by gathering and transporting the material 14% faster into the pre-compression chamber, compared with the MF 2270 XD model.

Sensors in Connecting Rods

Sensors in the connecting rods monitor the load on the plunger face, ensuring the double-acting density rams adjust the OptiForm Ultra bale chamber side doors and top press, for optimum settings to create Ultra density bales.

Automatic Density Control

Fully automatic density control delivers consistently dense, well-formed bales every time thanks to advanced, straightforward control using the latest Massey Ferguson BaleCreate user interface.

Ultra Knotters

The latest Ultra Knotters are specifically designed to handle the strain when using new, stronger and thicker twine developed for tying 20% heavier Ultra dense bales.

Six Knotters

Six knotters spaced evenly across the bale width help keep the area clear of debris, for reliable tying, bale after bale. Knotters are easily lifted for cleaning, with maintenance time reduced by AutoLube, automatic knotter lubrication.

Double Knot System

Consistent, trouble-free operation is assured because Hesston double knotters tie two knots in each string around the bale. Twines are under far less tension, compared with tying a single knot, which results in consistent tying each time, every time.

High Speed Stuffer Fork

Once full, the high-speed stuffer fork delivers the perfectly formed flake into the bale chamber, with optimum capacity.

BaleCreate

All baling operations are controlled easily via the fully ISOBUS compatible C1000 terminal and new exclusive BaleCreate user interface. The modern layout, with a choice of display screens, puts comprehensive control at the operator’s fingertips.

BaleCreate Home Screen

The BaleCreate home screen shows an overhead view of the baler, enabling operators to set and monitor a wide range of baler functions. Graphics indicate the load on each side of the plunger, with arrows guiding operators down uneven windrows.

BaleCreate Compatibility

BaleCreate loads automatically onto any ISOBUS compliant tractor terminal, displaying exactly the same screen and functions.

Available Models

Model |

Bale Size Width (mm) |

Plunger Speed (strokes/min) |

Pick-up Working Width (mm) |

|---|---|---|---|

| MF 2370 Ultra HD | 1,200 x 900 | 50 | 2,246 |

Share