Tractors

MF 9S

MF 8700 S

MF 8S

MF 7S

MF 6S

MF 5M

MF 5S

MF 5700 M

MF 4700 M

MF 3

MF 1700 M

MF 1700 E

MF 1500

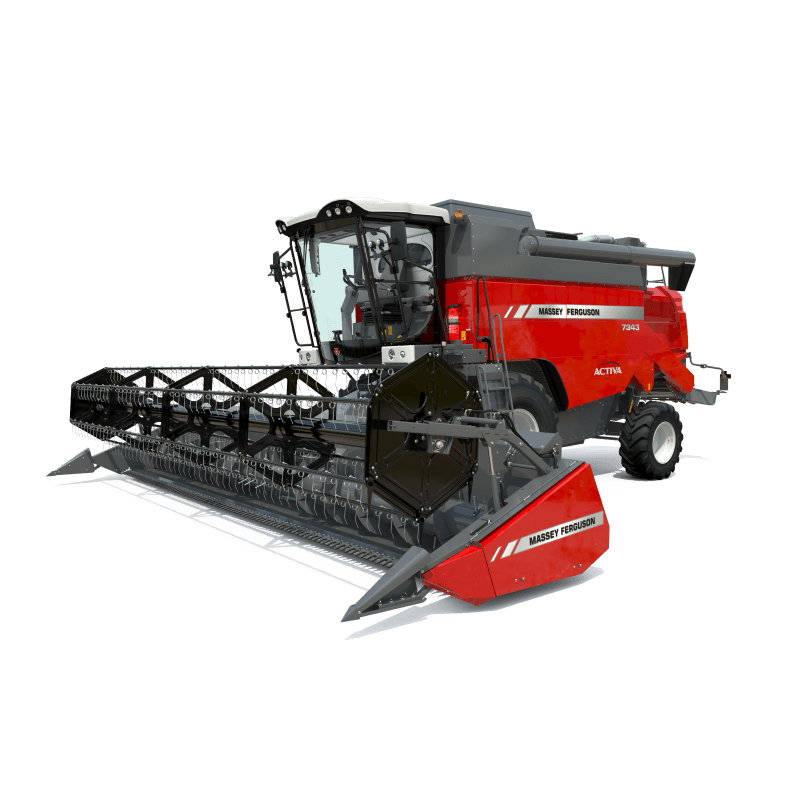

Combine Harvesters

MF IDEAL

MF Beta

MF Activa S

MF Activa

Balers

MF SB 1840

MF SB 1842S

MF LB 2200

MF RB F

MF RB F PROTEC

MF RB V

MF RB V PROTEC

MF TW

Hay and Forage

MF RK Series

MF DM Series

MF TD Series

Materials Handling

NEW MF TH

MF FL

MF FL X

Rotary Rakes

Excellent raking quality, easy handling and a durable design - these qualities give you good reason to buy a Massey Ferguson rake.

Current Offers & Promotions

No Results Found

Key Benefits

Technology & Innovation

- Single Rotor

- Two-Rotor or Four-Rotor

- Two-Rotor Central Delivery

- Two-Rotor Side Delivery

- Four-Rotor Central Delivery

Excellent raking quality, easy handling and a durable design – these qualities give you good reason to buy a Massey Ferguson single-rotor rake.

Rake Head

Cam Track

Modern and Proven Design

Swath Deposit to the Right

Special Bolt-On Connection

Tine Support

Tine Fixture

Perfect Working Height

Tangentially Arranged Tine Arms

Power Train

LED LIGHTING

These days, large rakes are key machines in the forage harvesting chain – a failure can result in the stoppage of other harvesting machinery, and could be the cause of large cost implications and disruptions. You should therefore entertain no compromises with your new rake. Massey Ferguson has combined its years of experience with the latest technical knowledge and, from these, developed a range of high performance large-scale rakes.

Rake Head

Cam Track

Jet Effect

Hilly Terrain Adaptation

Fully Cardanic Rotor Suspension

No Ground Penetration

SteerGUARD

SteerGUARD - Steering Movement

SteerGUARD - Direct Transmission of Steering Movement

Tangentially Arranged Tine Arms

Automatic working width pre-selection, tidy raking work, precisely deposited swaths and quick and safe travel from field to field, are all offered by the MF RK 662, MF RK 762, MF RK 802 and MF RK 1002 two-rotor central delivery rakes. They can master any working situation. With the optional 6-wheel contact-sensing chassis and the cardanic suspension of the rotors, tidy and loss-free raking work is always achieved. The best starting point for your high quality forage.

Automatic Height Limitation

Adjustable Working Width

PRO Models

PRO Models - Twin Leading Wheels

MF RK 702 TR-SDX, MF RK 662 SD-TRC, MF RK 772 SD-TRC, MF RK 842 SD-TRC Gen2 and MF RK 842 SD-TRC PRO Gen2

Two-Rotor Side Delivery Rakes

Large Overlaps Between Rotors

MF RK 702 TR-SDX Drawbar

MF RK 1254 TRC-EC, MF RK 1254 TRC Gen2, MF RK 1254 TRC-PRO Gen2 and MF RK 1404 TRC-PRO Gen2

Four-Rotor Central Delivery Rake

Four-Rotor Rakes Construction

Air Brake System

Headland Control System

MF RK 1254 TRC EC Safety Options

Quick Transport Speed

PRO Models and ISOBUS

Section Control Pro option

Available Models

Model |

Machine designation |

Working Width (m) |

Number of Rotors |

Tine arms per rotor |

|---|---|---|---|---|

| MF RK 341 DN | Three-point linkage, Single-rotor rake, Floating headstock | 3.4 | 1 | 8-3 |

| MF RK 361 DN | Three-point linkage, Single-rotor rake, Floating headstock | 3.6 | 1 | 10-4 |

| MF RK 381 DN | Three-point linkage, Single-rotor rake, Floating headstock | 3.8 | 1 | 10-4 |

| MF RK 391 DN | Three-point linkage, Single-rotor rake, Floating headstock | 3.85 | 1 | 10-4 |

| MF RK 421 DN | Three-point linkage, Single-rotor rake, Floating headstock | 4.2 | 1 | 12-4 |

| MF RK 451 DN | Three-point linkage, Single-rotor rake, Floating headstock | 4.5 | 1 | 12-4 |

| MF RK 451 TR | Single-rotor rake, Tractor linkage drawbar/hitch | 4.5 | 1 | 12-4 |

| MF RK 702 TR-SDX | Two-rotor rake, Side swath delivery | 7 | 2 | 12-4 |

| MF RK 662 SD-TRC | Two-rotor rake, Side swath delivery | 6.65 | 2 | 10 |

| MF RK 772 SD-TRC | Two-rotor rake, Side swath delivery | 7.7 | 2 | 12-4 |

| MF RK 842 SD-TRC | Two-rotor rake, Side swath delivery | 8.4 | 2 | 13-4 |

| MF RK 842 SD-TRC PRO | Two-rotor rake, Side swath delivery | 8.4 | 2 | 13-4 |

| MF RK 662 TRC | Two-rotor rake, Centre swath delivery | 6.6 | 2 | 10-4 |

| MF RK 762 TRC | Two-rotor rake, Centre swath delivery | 7.6 | 2 | 12-4 |

| MF RK 802 TRC | Two-rotor rake, Centre swath delivery | 8 | 2 | 12-4 |

| MF RK 802 TRC PRO | Two-rotor rake, Centre swath delivery | 8 | 2 | 12-4 |

| MF RK 1002 TRC | Two-rotor rake, Centre swath delivery | 10 | 2 | 15-5 |

| MF RK 1002 TRC PRO | Two-rotor rake, Centre swath delivery | 10 | 2 | 15-5 |

| MF RK 1254 TRC EC | Centre swath delivery, Four-rotor rake | 12.5 | 4 | 12-4 |

| MF RK 1254 TRC Gen2 | Centre swath delivery, Four-rotor rake | 12.5 | 4 | 12-4 |

| MF RK 1254 TRC PRO Gen2 | Centre swath delivery, Four-rotor rake | 12.5 | 4 | 12-4 |

| MF RK 1404 TRC PRO Gen2 | Centre swath delivery, Four-rotor rake | 13.80 | 4 | 13-4 |

Customer Reviews & Testimonials

Simon Broad

The Broad family runs a mainly grassland enterprise over the 325 acres of slightly undulating medium loam, split between two farms around Penshurst, in Kent.

Steve Horn

“With the 662, whatever the working width chosen, the height is automatically reduced for transport purposes to aid stability and avoid low branches. The geometry of the steering linkage certainly aids manoeuvrability and it travels well at speed.”

Share

https://www.masseyferguson.com/en_gb/product/hay-and-forage/mf-rakes.html