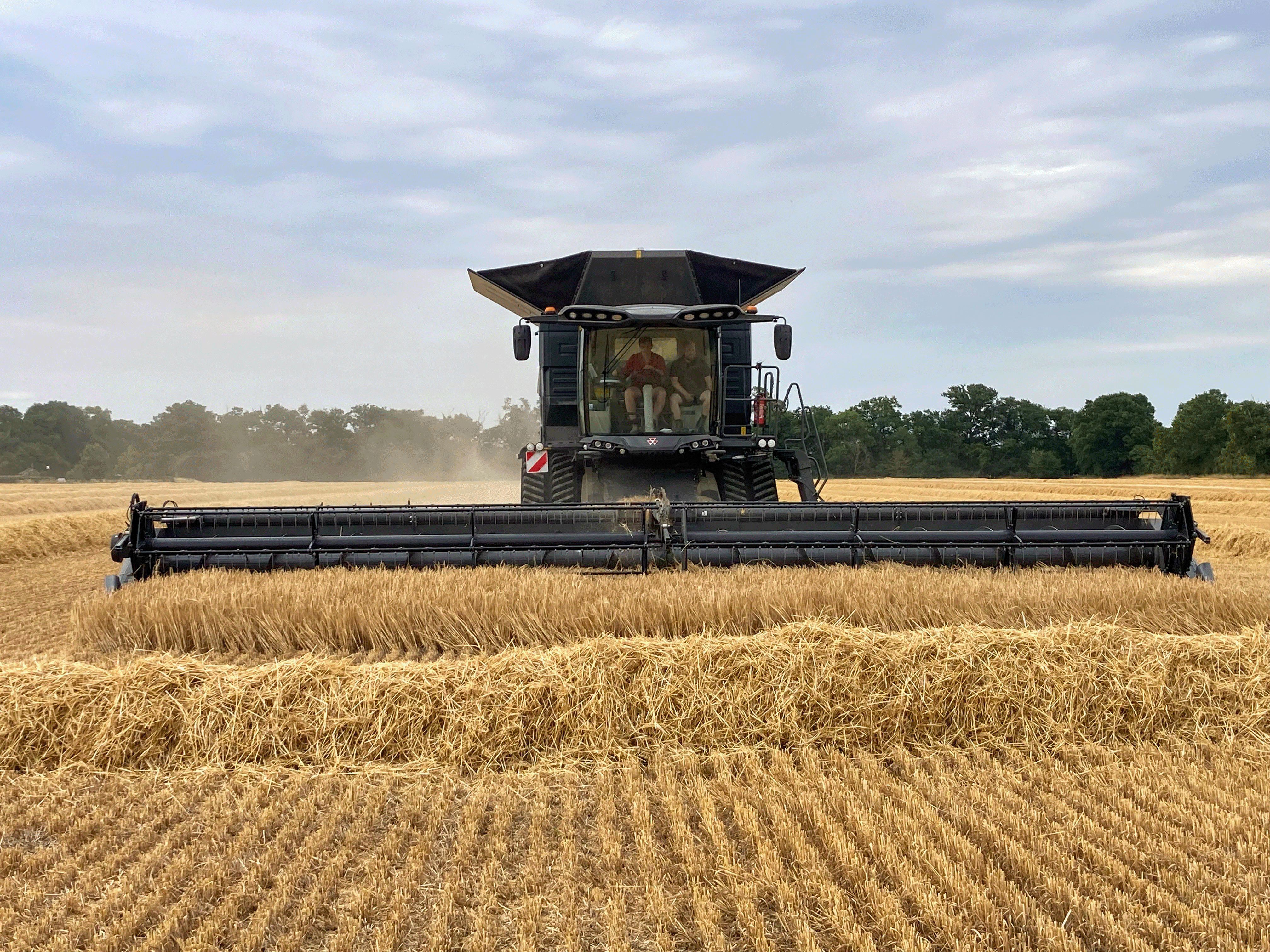

A SUCCESSFUL TRANSITION TO THE MF IDEAL 9T

For a Suffolk family farm, changing from a combine brand they knew well to a new Massey Ferguson IDEAL 9T two years ago required a leap of faith in both the manufacturer and dealer.

“When we changed to a direct drilling and minimal cultivations crop establishment regime, we also moved to controlled traffic farming to protect our heavy soils,” explained David Scott, who runs Bedingfield Hall Farm with his wife, Di, and their son, Will. “That meant a wider, 12 m combine was needed, so grain trailers could remain on the 36 m tramlines.”

The right machinery.

Approximately 720 ha of crops include winter wheat, oilseed rape, winter and spring barley, spring beans, sugar beet and vining peas. “We also own a traditional butchers’ shop in Framlingham and have several diversification projects, but the arable farming operation is our priority,” explained David. “Key to its success is investing in the right machinery, maintaining high standards and having excellent staff.” Following a successful demonstration in 2021, an MF IDEAL 9T with a 12 m PowerFlow header was ordered from local dealer, Thurlow Nunn Standen (TNS). “It gives us spare capacity,” David continued. “Without pushing it hard, spot harvesting rates of 80 t/hr in a 10–11 t/ha crop of wheat are achieved, but the average is closer to 45–50 t/hr, or 4.5 ha/h, as a lot of time is lost moving between fields.

“In variable weather we make the most of good harvesting opportunities, avoiding field damage when it’s wet, and ensuring produce is in optimum condition when it goes into store.”

Spacious, comfortable cab.

The combine’s main operator, Ben Reeve, likes the spacious and comfortable cab, with narrow front corner pillars allowing an excellent view across the wide header. “The automation works well. Everything is adjusted from the cab, and I usually start new crops using stored settings, then make fine adjustments to suit the conditions. Even in heavy crops, we achieve a clean sample with minimal losses, and in variable crops the travel speed adjusts to maintain an even crop flow, but without exceeding separation capacity. I love operating it.”

“We put a lot of effort into growing crops, so we don’t want to lose them out of the back,” agreed David. “The separating performance in oilseed rape is very good, and the gentle threshing action means we don’t worry about skinning malting barley.”

“Straw is left in excellent condition for baling, and an updated chopper fitted last year achieves a consistent fine chop, and even distribution across the 12 m cut width.”

Exceeded expectations.

“Our MF IDEAL 9T has exceeded our expectations. It’s easy to look after, and daily checks are minimal. Ownership and running costs are reasonable. We fixed our costs with a service plan and achieved average fuel consumption of only 62 l/hr in heavy wheat crops last harvest. The back-up from TNS Regional Sales Manager (Massey Ferguson), Ben Hockley, and the rest of the dealer team is excellent, and we are constantly reassured that manufacturer product specialists listen and react to our feedback,” David concluded.

After this exclusive testimonial of Mr Scott, do you want to discover more about the MF IDEAL combine range? Check now our website or contact your MF dealer!

Share