When it comes to drying hay, it’s nearly impossible to beat Mother Nature.

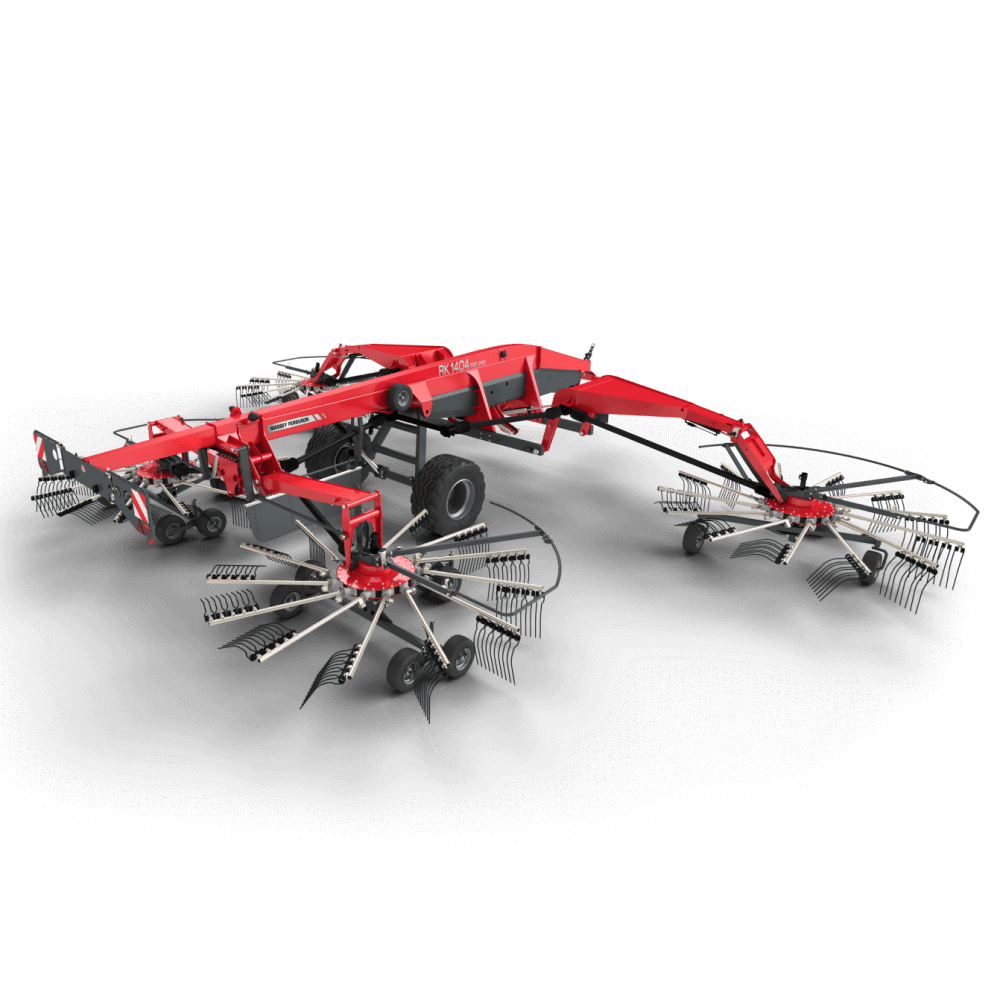

Of course, farmers have utilised nature’s resources – like the wind and sun – for as long as seeds have been planted in the ground. Today, you can accelerate Mother Nature’s gifts by spreading the crop with a professional-grade Massey Ferguson TD Series tedder.

Key Benefits

Technology & Innovation

Tine Arms

Sturdy Frame Joints

Rotor Head

Power Train

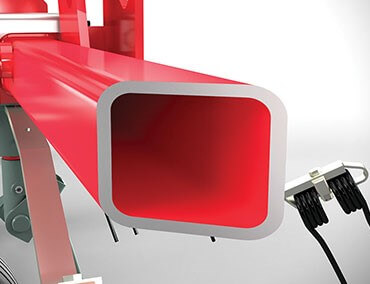

Square Frame Tubes

As with all Massey Ferguson hay tedders, the forage is picked up by the tines and turned gently, without damage. A light, loose and well mixed mat of forage is created, to help ensure a top quality end-product.

Comb Effect

Equal-Sided Tines

Tine Loss Protection

Super C Tine

Super C Quality

The new MF TD X tedder offers many benefits to users, thanks to its unique hook-shaped tines, which operate at the perfect speeds to deliver unsurpassed tedding capacity.

Hook-Shaped Tines Tedding Action

Flexible Hooked Tines

Hooked Tines - Better Spreading

Hooked Tines - Shorter Tine Movement

Hooked Tines - Longer Tines Movement

Thanks to the SLS (Security Lock System) from Massey Ferguson, maximum safety for your machine is guaranteed during folding operations.

SLS - Security Lock System

Available Models

Model |

Machine Designation |

Working Width (m) |

Number of Rotors |

Tine arms per rotor |

|---|---|---|---|---|

| MF TD 434 DN | Three-point linkage, Alpine | 4.3 | 4 | 6 |

| MF TD 454 DN | Three-point linkage | 4.5 | 4 | 6 |

| MF TD 524 DN | Three-point linkage | 5.2 | 4 | 6 |

| MF TD 576 DN | Three-point linkage, Alpine | 5.7 | 6 | 5 |

| MF TD 676 DN | Three-point linkage | 6.6 | 6 | 6 |

| MF TD 776 DN | Three-point linkage | 7.7 | 6 | 6 |

| MF TD 868 DN | Three-point linkage | 8.6 | 8 | 6 |

| MF TD 1110 DN | Three-point linkage | 10.7 | 10 | 6 |

| MF TD 776 TRC | Transport chassis | 7.7 | 6 | 6 |

| MF TD 868 TRC | Transport chassis | 8.6 | 8 | 6 |

| MF TD 1008 TRC | Trailed Tedder | 10.2 | 8 | 6 |

| MF TD 1310 TRC | Transport chassis | 12.7 | 10 | 6 |

| MF TD 1008 TR HYDRO | Trailed Tedder | 10.2 | 8 | 6 |

| MF TD 1310 TR HYDRO | Trailed Tedder | 12.7 | 10 | 6 |

| MF TD 776 X DN | Hook Tines | 7.7 | 6 | 6 |

| MF TD 1028 X TRC | Hook Tines | 10.2 | 8 | 7 |

| MF TD 1310 X TRC | Hook Tines | 12.5 | 10 | 7 |

Available Models

Model |

Machine Designation |

Working Width (m) |

Number of Rotors |

Tine arms per rotor |

|---|---|---|---|---|

| MF TD 404 DSR | Three-point linkage, Alpine | 4.0 | 4 | 5 |

| MF TD 404 DN | Three-point linkage, Alpine | 4.0 | 4 | 5 |

| MF TD 434 DN | Three-point linkage, Alpine | 4.3 | 4 | 6 |

| MF TD 576 DN | Three-point linkage, Alpine | 5.7 | 6 | 5 |

| MF TD 454 DN | Three-point linkage | 4.5 | 4 | 6 |

| MF TD 524 DN | Three-point linkage | 5.2 | 4 | 6 |

| MF TD 676 DN | Three-point linkage | 6.6 | 6 | 6 |

| MF TD 776 DN | Three-point linkage | 7.7 | 6 | 6 |

| MF TD 868 DN | Three-point linkage | 8.6 | 8 | 6 |

| MF TD 1110 DN | Three-point linkage | 10.7 | 10 | 6 |

| MF TD 776 TRC | Transport chassis | 7.7 | 6 | 6 |

| MF TD 868 TRC | Transport chassis | 8.6 | 8 | 6 |

| MF TD 1008 TRC | Trailed Tedder | 10.2 | 8 | 6 |

| MF TD 1310 TRC | Transport chassis | 12.7 | 10 | 6 |

| MF TD 776 X DN | Hook Tines | 7.7 | 6 | 6 |

| MF TD 1028 X TRC | Hook Tines | 10.2 | 8 | 7 |

| MF TD 1310 X TRC | Hook Tines | 12.5 | 10 | 7 |

Share

https://www.masseyferguson.com/en_il/product/hay-and-forage/mf-tedders.html