Tractors

MF 9S

MF 9S

Outstanding Design, Ultimate Performance

MF 8700 S

MF 8700 S

Where high horsepower & precision farming meet

MF 8S Xtra

MF 8S Xtra

Designed by Farmers for Farmers

MF 8S

MF 8S

Where Innovation Meets Performance.

MF 7S

MF 7S

The Professional

MF 6S

MF 6S

Concentrated Performance

MF 5S

MF 5S

The ultimate all rounder

MF 5M

MF 5M

Affordable efficiency

MF 6700

MF 6700

Born to Surprise

MF 5700

MF 5700

Born Adaptable

MF 4700

MF 4700

Born to Work

MF 3

MF 3

Specialists like you!

MF 2600

MF 2600

Your Rugged Workhorse

MF 2800 M

MF 2800 M

Premium machines for those who demand more.

MF 2800 E

MF 2800 E

A hard-working tractor for hard-working folks.

MF 1800 M

MF 1800 M

Premium machines for those who demand more.

MF 1800 E

MF 1800 E

Dependable. Versatile. Practical. Just like you.

MF 1GC

MF 1GC

GC Series Compact Tractor. Perfect All-Rounder.

Hay and Forage

MF Disc Mowers

MF Disc Mowers

Innovative and Efficient Mowers & Mower Conditioners

MF 1300 Conditioners

MF 1300 Conditioners

Smooth cut. Superb conditioning.

MF Self-Propelled Windrower

MF Self-Propelled Windrower

The smarter, more powerful way to better hay

MF 5400 Series Draper Headers

MF 5400 Series Draper Headers

Built from the ground up.

MF 9300 Series Disc Headers

MF 9300 Series Disc Headers

A cut above the rest.

MF Tedders

MF Tedders

Latest Generation of High Output Tedders

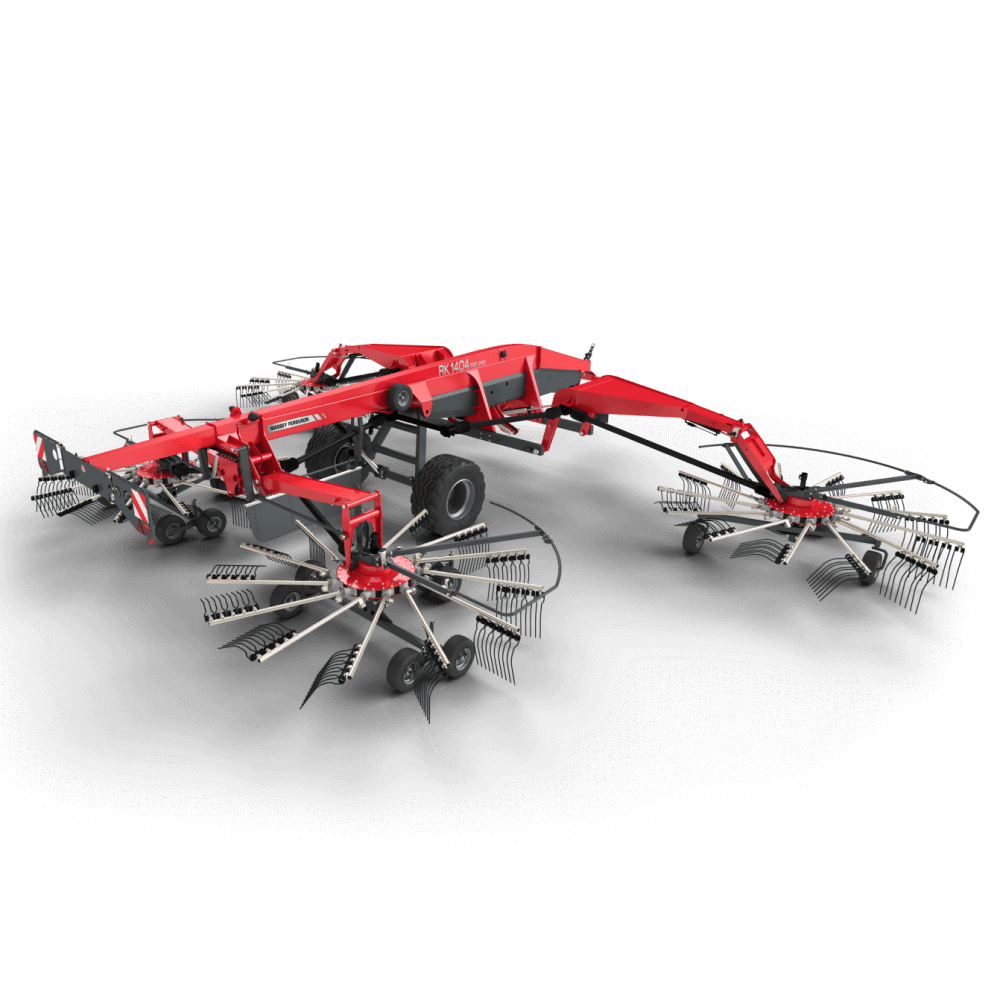

MF Rakes

MF Rakes

High Performance Range of Rakes

Balers

MF 1840

MF 1840

Straightforward Baling

MF 1842S

MF 1842S

High capacity small square baler

MF 2200

MF 2200

Outstanding Performance

MF 2200 New Gen

MF 2200 New Gen

Outstanding Performance

MF RB F

MF RB F

High output and cost effective

MF RB F PROTEC

MF RB F PROTEC

Non-stop excellence

MF RB V

MF RB V

High output and cost effective

MF RB V PROTEC

MF RB V PROTEC

Non-stop excellence

MF TW

MF TW

Reliable and robust

Materials Handling

MF FL Front Loaders

MF FL Front Loaders

Hard working, high performance loaders

MF FL X Front Loaders

MF FL X Front Loaders

When time’s not on your side, we are.

Compact Loaders & Backhoes

Compact Loaders & Backhoes

Ready for the tough tasks.

MF TH Telehandlers

MF TH Telehandlers

A New Era of Comfort and Productivity

Sprayers

MF 500R Series

MF 500R Series

Uncomplicated, Efficient, Economical and Sustainable

Dairy & Mixed Farming

Balers

MF 1840

MF 1840

Straightforward Baling

MF 1842S

MF 1842S

High capacity small square baler

MF 2200

MF 2200

Outstanding Performance

MF 2200 New Gen

MF 2200 New Gen

Outstanding Performance

MF RB F

MF RB F

High output and cost effective

MF RB F PROTEC

MF RB F PROTEC

Non-stop excellence

MF RB V

MF RB V

High output and cost effective

MF RB V PROTEC

MF RB V PROTEC

Non-stop excellence

MF TW

MF TW

Reliable and robust

Tractors

MF 7S

MF 7S

The Professional

MF 6S

MF 6S

Concentrated Performance

MF 6700

MF 6700

Born to Surprise

MF 5S

MF 5S

The ultimate all rounder

MF 5700

MF 5700

Born Adaptable

MF 4700

MF 4700

Born to Work

MF 2600

MF 2600

Your Rugged Workhorse

Sprayers

MF 500R Series

MF 500R Series

Uncomplicated, Efficient, Economical and Sustainable

Hay and Forage

MF 1300 Conditioners

MF 1300 Conditioners

Smooth cut. Superb conditioning.

MF Disc Mowers

MF Disc Mowers

Innovative and Efficient Mowers & Mower Conditioners

MF Self-Propelled Windrower

MF Self-Propelled Windrower

The smarter, more powerful way to better hay

MF 9300 Series Disc Headers

MF 9300 Series Disc Headers

A cut above the rest.

MF Tedders

MF Tedders

Latest Generation of High Output Tedders

MF Rakes

MF Rakes

High Performance Range of Rakes

Broad Acre

Balers

MF 2200

MF 2200

Outstanding Performance

MF 2200 New Gen

MF 2200 New Gen

Outstanding Performance

Tractors

MF 8700 S

MF 8700 S

Where high horsepower & precision farming meet

MF 8S

MF 8S

Where Innovation Meets Performance.

MF 7S

MF 7S

The Professional

Sprayers

MF 500R Series

MF 500R Series

Uncomplicated, Efficient, Economical and Sustainable

Hay and Forage

MF Disc Mowers

MF Disc Mowers

Innovative and Efficient Mowers & Mower Conditioners

MF Self-Propelled Windrower

MF Self-Propelled Windrower

The smarter, more powerful way to better hay

MF 9300 Series Disc Headers

MF 9300 Series Disc Headers

A cut above the rest.

MF 5400 Series Draper Headers

MF 5400 Series Draper Headers

Built from the ground up.

MF Tedders

MF Tedders

Latest Generation of High Output Tedders

MF Rakes

MF Rakes

High Performance Range of Rakes

Municipal & Grounds Care

Tractors

MF 7S

MF 7S

The Professional

MF 6S

MF 6S

Concentrated Performance

MF 6700

MF 6700

Born to Surprise

MF 5S

MF 5S

The ultimate all rounder

MF 5700

MF 5700

Born Adaptable

MF 4700

MF 4700

Born to Work

Horticulture/Viticulture

Tractors

MF 6700

MF 6700

Born to Surprise

MF 5700

MF 5700

Born Adaptable

MF 4700

MF 4700

Born to Work

MF 3

MF 3

Specialists like you!

Sprayers

MF 500R Series

MF 500R Series

Uncomplicated, Efficient, Economical and Sustainable

Lifestyle

Balers

Tractors

MF 4700

MF 4700

Born to Work

MF 2600

MF 2600

Your Rugged Workhorse

MF 2800 M

MF 2800 M

Premium machines for those who demand more.

MF 2800 E

MF 2800 E

A hard-working tractor for hard-working folks.

MF 1800 M

MF 1800 M

Premium machines for those who demand more.

MF 1800 E

MF 1800 E

Dependable. Versatile. Practical. Just like you.

MF GC1700

Trailed Round Baler Wrapper

The MF TW 130 and MF TW 160 are easy to use straightforward wrappers with a grid frame and exceptionally low wrapping table.

Key Benefits

Film Overlap

The correct film overlap is ensured by the ratio of bale rotation speed and the speed of the wrapping table. The guides on the wrapping table make sure that the bale remains firmly positioned in the centre of the table.

MF TW Arms

The MF TW 130 and MF TW 160 are easy to use straightforward wrappers with a grid frame and exceptionally low wrapping table. They’re equipped with a strong, welded loading arm that can be adjusted between 0.9m and 1.60m. The arm can lift bales up to 1.30m diameter (max. 1000kg) for the MF TW 130 and up to 1.60m diameter (max. 1250kg) for the MF TW 160.

Adjustable Film Layers

Depending on the crop and conditions, the operator can easily adjust the required number of film layers. The pre-stretching device is designed to work with 500mm or 750mm rolls and can be set at 55% or 70% stretch for tighter wrapping and reduced film consumption. A quick-lock system makes the replacement of empty rolls fast and easy. Storage positions provide the facility to carry up to 3 extra rolls of film.

Bale Discharge

Bale discharge is exceptionally gentle, without the risk of damaging the wrapped bale or the ground, thanks to a lowpositioned wrapping table which tilts close to the ground when unloading bales.

Transport

On the MF TW 130 the right-hand side transport wheel can be turned around the centre spindle, extending the overall transport width from only 2.30m to 2.85m, thus increasing the overall wrapper stability. As an additional function, the MF TW 130 & MF TW 160 wrappers can be used to transport one or two pre-wrapped bales from the field.

Technology & Innovation

Transport Wheel

On the MF TW 130 the right-hand side transport wheel can be turned around the centre spindle, extending the overall transport width from only 2.30m to 2.85m, thus increasing the overall wrapper stability.

Welded Loading Arm

MF TW 130 and MF TW 160 are equipped with a strong, welded loading arm that can be adjusted between 0.9m and 1.60m. The arm can lift bales up to 1.30m diameter (max. 1,000kg) for the MF TW 130 and up to 1.60m diameter (max. 1,250kg) for the MF TW 160.

Transport Pre-Wrapped Bales

MF TW 130 & MF TW 160 wrappers can be used to transport one or two pre-wrapped bales from the field.

Bale Discharge System

The MF TW 160 is fitted with a width adjustable active bale discharge system. When the bale is tipped off the wrapping table the discharge table lifts to catch the bale and gently lowers it to the ground, eliminating any film damage.

Gentle Bale Discharge

Bale discharge is exceptionally gentle, without the risk of damaging the wrapped bale or the ground, thanks to a low-positioned wrapping table which tilts close to the ground when unloading bales.

Optional Bale Tipper

An optional baler tipper is available to prevent the bales from rolling in hilly conditions, improving safety and reducing by up to 15% the time required for transport/loading and for bale collections in the field.

Film Layers

The operator can easily adjust the required number of film layers. The pre-stretching device is designed to work with 500mm or 750mm rolls and can be set at 55% or 70% stretch for tighter wrapping and reduced film consumption.

Film Storage

A quick-lock system makes the replacement of empty rolls fast and easy. Storage positions provide the facility to carry up to 3 extra rolls of film.

Film Overlap

The correct film overlap is ensured by the ratio of bale rotation speed and the speed of the wrapping table. The guides on the wrapping table make sure that the bale remains firmly positioned in the centre of the table.

E-Link Plus

The MF TW 160 is equipped with the ‘E-link Plus’ control box. This easy to use system allows semi-automatic or fully automatic control of the wrapper. The complete process from loading through to discharge is controlled with minimum effort.

MF TW 130 Controls

The MF TW 130 is equipped with very simple semi-automatic controls, for fast and reliable trouble-free operation.

Available Models

Model |

Control |

Bale Diameter (m) |

Approximate weight (kg) |

|---|---|---|---|

| MF TW 130 | Semi-Automatic | 0.9 - 1.3 | 1,080 |

| MF TW 160 | Automatic | 0.9 - 1.6 | 2,110 |

Products & Services to compliment your MF TW

Available service packages

A little extra care goes a long way – fields and fields further.

-

AGCO Support

ExploreWhen you invest in a Massey Ferguson machine you are backed by AGCO, the world’s largest agricultural machinery company.

-

Servicing Options

ExploreProtect your investment in Massey Ferguson with an industry leading service and warranty contract.

-

Technical Literature

ExploreAGCO’s RMI website provides independent operators with access to AGCO’s Repair and Maintenance Information.

Related products & equipment

Approach the task at hand with the right tool for the right job.

-

MF 4700

Born to Work

ExploreMassey Ferguson has always provided innovative, but practical solutions to the farmer’s needs to answer the challenges of the time. The MF 4700 Global Series continues this tradition by offering a highly modern, high performance, heavy duty, straightforward range of tractors that provide exceptional efficiency for every type of farmer all over the world.

-

MF 5700

Born Adaptable

ExploreWith this new and straightforward range of tractors, Massey Ferguson has taken the concept of the sub-130hp tractor and re-engineered it from the ground up to meet the needs of present and future farming.

-

MF 5S

The ultimate all rounder

ExploreSimply the ultimate all-rounder tractor between 105hp and 145hp, the new MF 5S Series offers a choice of five models with a totally new, upgraded design incorporating the iconic sabre line livery.

-

MF 6700

Born to Surprise

ExploreWith this new and straightforward range of tractors, Massey Ferguson has taken the concept of the sub-130hp tractor and re-engineered it from the ground up to meet the needs of present and future farming.

-

MF 6S

Concentrated Performance

ExploreThe new MF 6S continues the tradition launched with the iconic MF 8S, imposing itself as a straightforward and dependable tractor : operating your MF 6S you’ll experience amazing power, agility, engineered quality and distinctive style day after day.

Parts Packages

Customised to your need, repaired at your speed.

-

AGCO Reman

ExploreAGCO Reman is the name for our range of remanufactured products. This is a systematic process where previously used parts are recovered and sent to a remanufacturing centre of excellence and brought back to as new condition.

-

Complementary Products

ExploreYour Massey Ferguson dealer has a huge range of Complementary Products which makes them a one-stop shop for all your farming needs.

-

Dealer Fit Accessories

ExploreGenuine Massey Ferguson accessories offer the same high levels of durability and performance expected of the Massey Ferguson machine.

-

Genuine AGCO Parts

ExploreAGCO Parts are the only genuine and original replacement parts for Massey Ferguson.

-

Parts Books

ExploreOur AGCO Parts Books, available on web and mobile, provides you with access to an electronic catalog where you can easily find replacement part information for your Massey Ferguson machine at any time.

Latest News

Go to Newsroom

Massey Ferguson Australia introduces the MF 9S – the new straightforward and dependable fleet flagship

Read More

Massey Ferguson introduces the MF 8S Xtra featuring comfort and efficiency upgrades.

Read More

Massey Ferguson introduces six models from 95hp to 145hp in the new MF 5M Series

Read More

Massey Ferguson 5M Series tractors win respected Red Dot Award: Product Design 2025

Read More

MF 6S.180 Dyna-VT wins prestigious Tractor of Spain 2024/25 award in the 101-200hp category

Read MoreSelect your market

Globally welcome, locally specialised. Choose your market below or go straight to our International-English site.

Find a Dealer

Google maps requires cookies enabled to work correctly.

Share