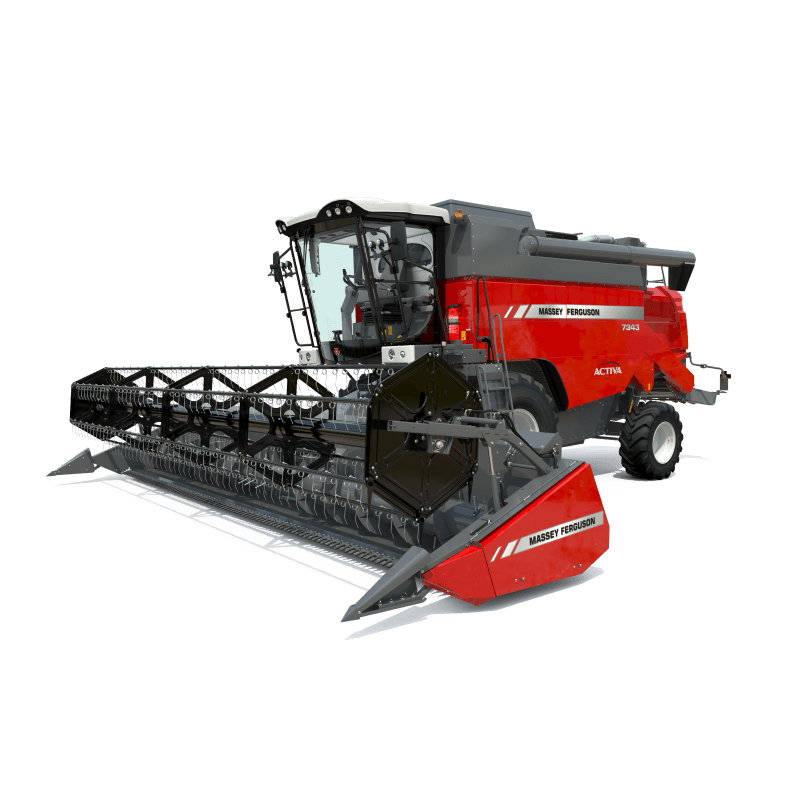

Significant upgrades boost MF LB 2200 Series large square baler performance

Building on the success of its predecessor, the MF LB 2200 Series brings significant updates and new features to further enhance performance.

The large square baler range retains five models covering four bale sizes. New model numbers have been introduced.

These square balers make dense, well-formed bales, and are renowned for their reliability, longevity and low cost of ownership.

Current Offers & Promotions

Guidance Offer | 135 - 425 HP

Enhance your farming performance

MF 6S, MF 7S, MF 8S or MF 9S with up to €10,000* discount on the MF Technology Pack

Valid until December 31, 2025

MF 5M & MF 5S Elevate your comfort!

Elevate your comfort!

Valid until December 31, 2025

T&C apply*.

Key Benefits

Technology & Innovation

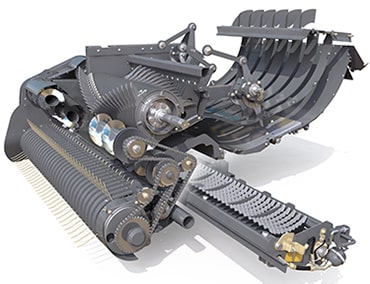

INCREASED PICK-UP PERFORMANCE

The pick-up on the MF LB 2200 Series features a new five-tine bar pick-up reel and a lighter weight wrapper made from polypropylene with a highly durable material. This new design allows faster ground speed, increased performance and smoother operation.

Polypropylene Wrapper Bands

By pivoting around the lower auger, there’s less to lift. Durable polypropylene wrapper bands further lighten the load, reduce noise and are quick and easy to replace.

ProCut

ProCut chops the crop to your required length and the packer tines ensure high capacity crop transition into the pre-compression chamber.

Packer System

The packer system ensures consistent flake formation producing perfect bale shape regardless of windrow shape and density.

PROCUT KNIVES

The MF LB 2233 has a cutter with up to 17 knives, while the MF LB 2224, MF LB 2234 and MF LB 2234 XD all have up to 26 knives. With all knives engaged – the chop length is 43.5mm and with a single knife-bank it is 87.0mm.

HYDRAULIC ACCUMULATORS

Each knife bank is protected by hydraulic accumulators which react quickly to prevent damage if a foreign object enters the cutting area.

PRE-COMPRESSION CHAMBER

The award-winning pre-compression chamber design from the previous MF LB 2200 Series benefits from a new more rigid wrapper for even better crop flow and reliability.

Stuffer Fork

Only when the chamber is perfectly full will the trip door activate, and the stuffer fork powers the fully formed flake into the bale chamber.

PLUNGER

Driven by an enormous gearbox with massive strength, the plunger is connected by two heavy-duty connecting rods.

Load Cells within Connecting Rods

Contained in these are load cells that measure the load on the plunger face. Information from the load cells is used to control the automatic density control system and also provides the operator with driving arrow guides if uneven swaths are encountered.

OPTIFORM BALE CHAMBER

The longer doors on models with the OptiForm bale chamber help to improve bale compression, ensuring an even better bale shape and consistent density through the bale.

MF 2234 XD MODEL

The MF 2234 XD has immense capabilities and easily produces bales containing 15% to 20% more material (than the standard MF 2234 model baler).

MF 2234 XD BALES

Designed specifically to lower transport costs with 1.2m x 0.9m bales, this machine produces much denser and heavier bales, further helping to optimise transport space and cut costs.

NEW TANDEM AXLE AND SUSPENSION

The MF 2200 Series is more stable on the road and in the field with a smoother ride thanks to a new axle design with asymmetric parabolic springs for maximum operator comfort and road safety.

STRONG ROLLER BALE CHUTE

The roller bale chute has been redesigned for extra strength, with one side mounted lifting ram and straps rather than chains.

TWINE MONITORING

The twine monitoring system, available as an option, measures the amount of twine used allowing operators to manage how much is left in the twine box and anticipate refills.

Double Acting Density Rams

Double acting density rams apply pressure to both the side and top chamber doors to give consistent bale density all controlled automatically via the C1000 Baler Monitor.

ROLLER CROP PRESS WINDGUARD

The high-capacity pick-up contributes to the baler’s impressive productivity, but the windguard with the roller crop press ensures that it is still gentle on the crop.

LED LIGHTS AND BEACON

New LED lights and a beacon can be fitted to ensure optimal vision in the field at night, and safety on the road.

TANDEM AXLE

The new tandem axle allows the fitment of wider tyre options while maintaining a narrow overall width below 3.00m. This makes transport easier and reduces soil structure and grass damage.

MF 2233 PROCUT BALER

On the narrower MF 2233 baler, a full width upper cross auger further improves feeding by powering the crop to the packer and pre-compression chamber. This positive, powered feeding maintains a smooth and constant material flow into the baler.

FIELDSTAR 5 TERMINAL

The proven Fieldstar 5 nine-inch colour, touch-screen control terminal features a new modern user interface to operate the MF 2200 Series baler. Data can be downloaded through the USB port.

ISOBUS BALER

The fully ISOBUS-compliant balers can work on any tractor fitted with the Datatronic 5 terminal, and use it to control and display baler settings.

TIM – TRACTOR IMPLEMENT MANAGEMENT

On TIM compliant tractors, the baler closely monitors the baling performance and automatically adjusts the combination’s travel speed according to parameters set by the user. The system allows the operator to fully focus on steering and the crop feed.

MF CONNECT TELEMETRY

MF Connect Telemetry enables customers to access information about the baler and its performance to make efficient and informed operational decisions. MF connected machines can all be monitored through a common interface for convenient fleet monitoring.

Video Cameras

The baler is pre wired in readiness for a video camera and the C1000 baler monitor is full colour and video compatible.

BALECREATE TERMINAL DISPLAY

BaleCreate gives the operator a whole new user experience with a modern and intuitive user interface to control and display information about the MF 2200. This ensures the operator can focus on maintaining optimum baler performance and productivity.

Bale Weighing System

The Integrated Bale Weighing System weighs the bale as it exits the chamber onto the roller bale chute.

STANDARD ELECTRONIC BALE LENGTH CONTROL

This feature ensures the desired bale length can be quickly set, and allows the operator to follow bale growth progress through the BaleCreate terminal display. This electronic system is standard, and helps improve accuracy, consistency and productivity.

Available Models

Model |

Bale Size (mm) |

Plunger Speed (strokes/min) |

Pick-up Working Width (mm) |

|---|---|---|---|

| MF 2233 | 80 x 90 | 47 | 2,250 |

| MF 2224 | 120 x 70 | 47 | 2,250 |

| MF 2234 | 120 x 90 | 47 | 2,250 |

| MF 2234 XD | 120 x 90 | 47 | 2,250 |

| MF 2244 | 120 x 130 | 33 | 2,250 |

Harvest Promise

AGCO’s Harvest Promise is our commitment to you that, in the exceptionalsituation we can’t get the parts to you in 48 hours, we will help you through our Dealer network or even contribute towards a contractor to step in and harvest your crop until you’re up and running again. For full terms and conditions and to register for the programme contact your local Massey Ferguson Dealer. Only available in selected markets.

Share