Tractors

MF 9S

MF 8700 S

MF 8S

MF 7S

MF 6S

MF 5M

MF 5S

MF 5700 M

MF 4700 M

MF 3

MF 1700 M

MF 1700 E

MF 1500

Combine Harvesters

MF IDEAL

MF Beta

MF Activa S

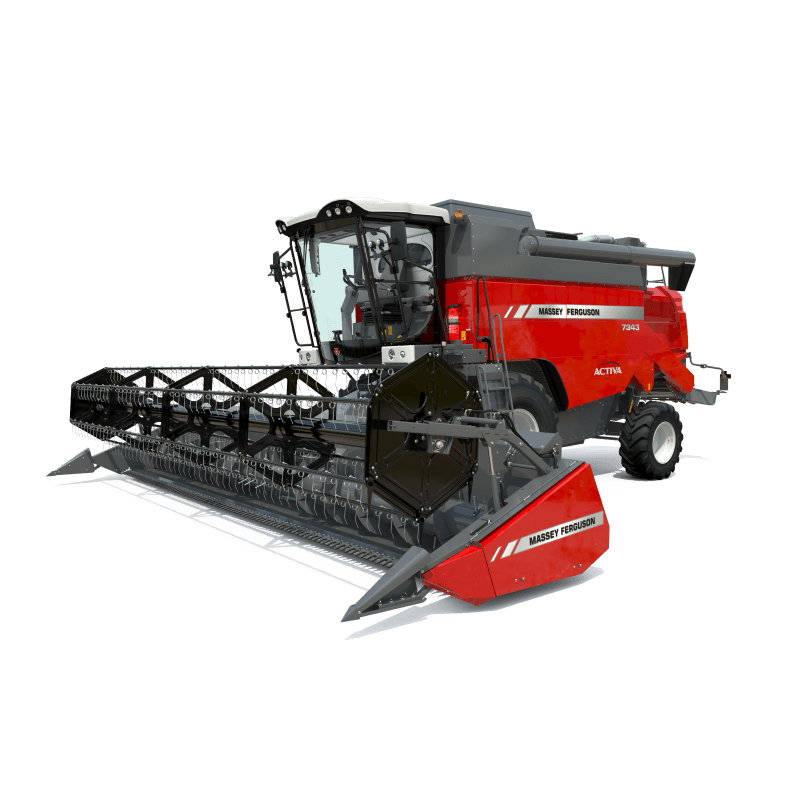

MF Activa

Balers

MF 1840

MF 1842S

MF 2200

MF RB F

MF RB F PROTEC

MF RB V

MF RB V PROTEC

MF TW

Hay and Forage

MF RK Series

MF DM & M Series

MF TD Series

Materials Handling

NEW MF TH

MF FL

MF FL X

A North Lincolnshire arable farming partnership has replaced a crawler and a mid-size wheel tractor with one Massey Ferguson 8737S, equipped with Michelin AxioBib IF tyres and a central tyre inflation system to optimise working efficiency.

A North Lincolnshire arable farming partnership is using the latest tyre technology to improve its operating efficiency and reduce costs by replacing a twin-track crawler with a more versatile Massey Ferguson wheeled tractor.

For the past 12 years a 320hp twin-track crawler performed most heavy cultivations and drilling tasks for Forward Farming LLP, near Brigg. The farming partnership includes three farms – JM Dodds, Lancaster & Sons and W Sowerby & Co, and also provides a contracting service for three other local farms which means the fleet of machinery effectively serves 1,250ha. Soils include sandy loam, Wold land and clay loams and crops include wheat, maize, barley, vining peas, oilseed rape and sugar beet.

“Our twin-track crawler had limited applications so for much of the year it was unused,” explained farmer, William Sowerby. “Our fleet also included three wheeled tractors – one of which did the ploughing and the others performed general field and transport work. “We have shared farm machinery for more than 30 years, and in my experience the key to getting value from a tractor is for it to be used throughout the year and work as many hours as possible, so when the crawler was due for replacement this year we looked at alternatives.”

William explained that options considered included a new twin-track crawler, various brands of half-track, and high-horsepower wheeled tractors. “The benefit of the crawler was that the tracks provide a large ground contact area which reduces compaction. However, a disadvantage of the twin-track design is that ridges are created during headland turns leaving the ground uneven for subsequent field tasks such as spraying through the growing season.”'

Latest technology

William enjoys an excellent working relationship with his local AGCO dealer, Peacock & Binnington which has a depot at Brigg, and he also owns a Massey Ferguson 7720S tractor which was purchased new from the dealer last year. He discussed options with Brand Manager Dan Woodall and Area Sales Representative Ian Hopper. “Moving from a nine-year old crawler with basic GPS steering, we were keen to make the most of the latest precision farming innovations including wireless data transfer between the tractor and farm office,” he said. “The most attractive option was the latest Massey Ferguson 8737S wheeled tractor with Michelin IF low ground pressure tyres and equipped with a central tyre inflation system allowing pressures to be reduced as low as possible for field work, then raised for road travel between work areas. We believed that with these tyres it could do the ploughing and all the heavy cultivations and would also be ideal for drilling, plus it could be used occasionally for trailer work.”

William consulted soil and cultivations specialist Philip Wright of Wright Resolutions before ordering the tractor. “Philip has worked with us previously and knows the farm and he agreed that what we were proposing made sense. There would be situations where a crawler might provide an advantage, but with central tyre inflation to optimise field and road performance, the versatility of a high-horsepower wheeled tractor made it the preferred option,” he said.

The twin-track crawler and a 230hp wheeled tractor were part exchanged for the ex-demonstration Massey Ferguson 8737S with up to 400 maximum horsepower. The tractor was specified with Michelin AxioBib IF 800/70R38 rear, and IF 600/70R30 front tyres, and a Michelin Zen@Terra central tyre inflation system was fitted by TractAir Ltd, which is based near Hull.

The Michelin Zen@Terra tyre inflation system allows pressures to be adjusted on the move.

Expert advice

Michelin tyre specialists weighed the tractor with various implements and provided recommendations for ballast and tyre inflation pressures for each task. The information for each operation is stored on the tractor’s Datatronic 5 terminal and the operator has only to select the appropriate activity on the terminal, from ploughing, subsoiling, drilling or transport etc, and the tyre pressures are adjusted accordingly. Inflation from the lowest working pressures to transport takes up to 15 minutes but reducing pressures for field work is much quicker. Pressure settings for new tasks are downloaded through a mobile phone app and sent by Bluetooth to the Zen@Terra unit.

In line with Michelin’s recommendations, the 8737S carries a 270kg belly weight, either 1,800 or 2,400kg front weights and a 250kg weight on the inside of each rear wheel. Usually two additional weights are carried on the outside of each rear wheel, but an additional weight can be added for extra traction, bringing the total to 2,000kg on the rear axle.

Successful investment

The tractor was delivered just before harvest and has since carried out most of its intended range of operations. It handles the farm’s Kverneland 7f fully mounted plough easily, ploughing on-land rather than in-furrow as before, and achieves an average working speed of 10kph with almost zero wheel slip. The heaviest work is with a seven-leg Simba Flatliner subsoiler, which was previously used only behind the crawler. “In wet conditions it pulls the Flatliner when the crawler would have struggled for grip, but in dry conditions the crawler pulled it more easily,” explained William. “With tyre pressures reduced to the lowest recommended, the Massey Ferguson does a great job with our drill, and the headlands are left much more level compared to the crawler.”

The Massey Ferguson 8737S pulls the 7f mounted plough with ease at 10kph in most working conditions, with the rear tyre pressures at 1.2 Bar and the fronts at 0.9 Bar. The tractor is equipped with GPS guidance and auto-steer, which makes it easy to work on-land rather than in the furrow, reducing compaction and providing a more comfortable ride.

The Massey Ferguson 8737S pulls the 7f mounted plough with ease at 10kph in most working conditions, with the rear tyre pressures at 1.2 Bar and the fronts at 0.9 Bar. The tractor is equipped with GPS guidance and auto-steer, which makes it easy to work on-land rather than in the furrow, reducing compaction and providing a more comfortable ride.

The cab is described as spacious and very comfortable. Mark said all around vision is excellent and there is lots of storage for odds and ends. For road and field work he selects the Dynamic Tractor Management (DTM) operating mode which automatically adjusts the engine and transmission for maximum efficiency. Ploughing at 10kph, the engine speed is usually 1,300rpm, rising to 1,500rpm when conditions are particularly tough. Mark said that the 8737S uses much less fuel than the crawler it replaced.

Peacock & Binnington Massey Ferguson Brand Manager Dan Woodall is pictured (left) with the 8737S main operator Mark Ansell.

Peacock & Binnington Massey Ferguson Brand Manager Dan Woodall is pictured (left) with the 8737S main operator Mark Ansell.

Efficient task management

The tractor’s data handling capabilities were used from the start, and William called upon the expertise of self-employed sprayer and combine operator, Jo Fewster to assist with setting up the on-board systems to communicate with the farm’s GateKeeper farm management software. Field maps and boundaries are sent from the farm’s sprayer to the farm office, then exported to the tractor with task instructions. Tramline positions are also shared so that the tractor wheels travel on the same ground as the sprayer. On completion, the tractor’s TaskDoc data recording system sends job reports to the office and William commented that as every task is logged from start to finish, accurate record keeping is guaranteed.

A useful new feature available through Massey Ferguson’s AutoGuide 3000 guidance system is that virtual inner boundaries can be created within main field boundaries, and William said that these are improving working efficiency. “Previously the operator judged where to lift and lower implements before and after each headland turn by eye, but the position varied resulting in an uneven finish and some ground was worked twice. Tramlines can be used as a physical marker, but if the implement is lifted and lowered precisely in line with the tramline then the sprayer operator is likely to have problems caused by uneven ground the next year. A solution is to create virtual inner boundaries on the field map, away from the tramlines, and then use it as a reference point for all field tasks. “We are really pleased with the level of technology available through the tractor, and the support from Peacock & Binnington’s Group Technology Brand Manager Stephen Mills. It’s proving user-friendly, there isn’t so much that it’s over-complex, and it provides real benefits.”

Mark Ansell describes the ride quality of the 8737S with its rear linkage suspension and the Michelin tyres as ‘brilliant’. He is pictured in the cab, while Peacock & Binnington Massey Ferguson Brand Manager Dan Woodall stands by the cab steps.

Ideal solution

“Having relied for many years on individual tractors for specific tasks, we now have a versatile tractor which has already proved itself ideal for ploughing, subsoiling, heavy cultivations and drilling, and which was also used for corn carting during harvest when a smaller tractor wasn't available,” added William. “This was just the result we were hoping for, and whereas the previous crawler worked only 800 hours per year we expect the 8737S to work up to 1,300. Compared to some other tractors we considered the Massey Ferguson was very competitively priced, but it was selected because we felt it would be the best machine for the job, and that is proving to be the case.”

Share

https://www.masseyferguson.com/en_ie/discover-mf/testimonials/william-sowerby.html