Tractors

MF 9S

MF 8700 S

MF 8S

MF 7S

MF 6S

MF 5M

MF 5S

MF 5700 M

MF 4700 M

MF 3

MF 1700 M

MF 1700 E

MF 1500

Combine Harvesters

MF IDEAL

MF Beta

MF Activa S

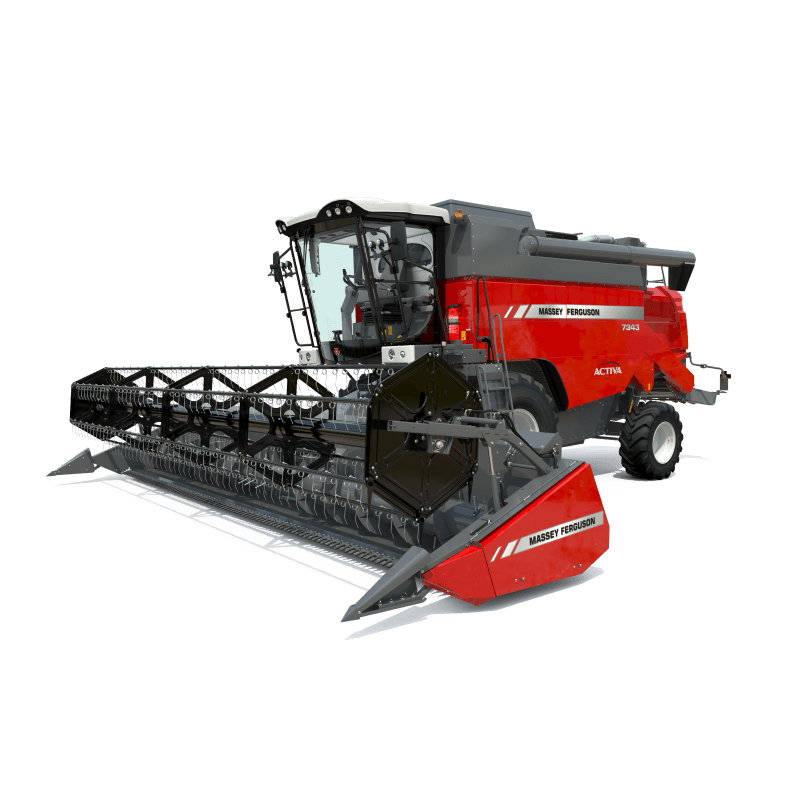

MF Activa

Balers

MF 1840

MF 1842S

MF 2200

MF RB F

MF RB F PROTEC

MF RB V

MF RB V PROTEC

MF TW

Hay and Forage

MF RK Series

MF DM & M Series

MF TD Series

Materials Handling

NEW MF TH

MF FL

MF FL X

It performed exceptionally well - that’s the verdict of a West Yorkshire-based farmer and contractor after his first harvest with a new Massey Ferguson Ideal 7 PL combine.

The contracting operation shares the farm’s machinery, and services include baling, cereal harvesting, arable field operations and fencing, plus digger work. “We don’t do much stubble-to-stubble contracting, but have many loyal customers within 20-miles of our base who rely on us for specific operations,” explained Chris. “Harvesting and baling are specialities and we run two round balers and two large square balers producing bales of different sizes.”

Massey Ferguson preferred

Massey Ferguson tractors dominate the fleet and there are also two Fendts - all supplied by AGCO main dealer Peacock & Binnington. There are also two older tractors of another brand. “We select Massey Ferguson tractors for their reliability,” explained Chris. “They offer great value for money and a good specification and we like using them.

“The dealer team is great too. We know everyone well, and there is always someone available at the end of the phone.”

Massey Ferguson combines have been used for many years, but as demand for the harvesting service grew, a second combine of another brand was purchased to work alongside the current Massey Ferguson 7280. “Running two straw-walker combines gave us the extra capacity we needed, but left us short of operators for straw baling. We also experienced constant problems with the second combine as it always skinned the malting barley. In 2017 we traded in both machines for an ex-demonstration Massey Ferguson Delta rotary with a 9.2m PowerFlow header which promised much higher output.”

The Delta performed well, but in 2019 Chris looked at the new Massey Ferguson Ideal as a potential replacement. “I’m an engineer and was impressed by its simple design, and especially the use of shaft drive instead of large numbers of belts. We discussed the Ideal with Peacock & Binnington Harvesting Sales Manager Andrew Whiteley and tried to arrange a demonstration. For various reasons it wasn’t possible so, with a big leap of faith and without trying it, we placed an order for a new Ideal 7 PL,” he added.

The new combine had 4wd and the latest 7.7m SuperFlow header - the first of its type in the UK, and Chris said he was immediately satisfied that he had made the right decision. “Even though the Ideal is on wheels rather than tracks, it’s under 3.5m wide, so moving it between farms is no problem,” he explained. “The header’s size allows it to be towed behind the combine, which means I can travel to a customer, harvest his crops and return home without needing a tractor or additional driver. The 4wd probably won’t be needed, but when customers are relying on us to harvest their crops at the optimum time, it’s reassuring to know that if the crop is fit but the ground is slippery, we can still operate.”

Impressive work rates

The Ideal 7 PL operated by West Yorkshire-based farmers and contractors C&R Moscrop & Sons. Pictured with it are Chris Moscrop (left), and Peacock & Binnington Harvesting Sales Manager, Andrew Whiteley

The 2020 harvest included many low-yielding crops which had been affected by poor conditions for establishment during winter and spring. However, in better wheat yielding 10t/ha, the Ideal 7 achieved spot work rates of 60t/hr with negligible grain loss. The Ideal’s HarvestPlus feature maintains a constant working load by adjusting the travel speed as crop density varies while also monitoring grain losses. Chris said that this worked well and responded very quickly to changes in working conditions. Average working speeds of 8–9kph were achieved with a throughput of 50–60t/hr in good wheat crops. “I hadn’t expected that sort of performance from a single-rotor combine, especially as we tend to cut stubbles short to maximise the amount of straw for baling,” he said.

Most straw is baled, and the combination of the 7.7m header and extended 9.15m folding unloading auger meant the swath wasn’t run down by grain trailers. Chris said the Ideal’s gentle threshing action left swaths in great condition. “A customer contacted us as soon as he started using the bales to compliment us on the excellent straw quality. It was the first time he had bought from us but he has already said he will have more this year, and that’s entirely due to the Ideal’s gentle handling.”

The SuperFlow header’s performance in oilseed rape was described by Chris as ‘unbelievable’. “It was a heavy, long-strawed crop last year, and I was amazed at the way the header fed it so smoothly with no bunching. The work rate was slightly slower than the more powerful Delta, but it produced a much cleaner sample with lower losses.”

Chris said customers were impressed by the Ideal’s ability to remove awns from winter barley. “A lot of farmers said that their own combines struggled last year, but the Ideal did a great job without threshing the crop aggressively,” he stressed.

Spring barley was also challenging as, although the grain was ripe, there was a lot of green straw. “A lot of what we harvest is grown for malting so treating the crop gently to avoid grain damage is essential. The Ideal’s long Helix rotor did a great job, and we had no problem obtaining a good sample with very low losses.”

The Superflow header’s tilt angle adjustment also helped. “The crop was brackled and heads were close to the ground, but tilting the header forwards and pushing the knife fingers right under the crop to lift it made harvesting easier, and very little was missed,” confirmed Chris.

Slopes tackled easily

Ideal combines are equipped with IDEALbalance, which ensures that crop separation, cleaning and losses are not affected by slopes up to 15 per cent. The Ideal 7 PL chosen by Chris also had the ParaLevel system, which adjusts the front axle to keep the whole machine level on slopes up to 14 per cent. This means that even on very steep slopes up to 29 per cent, the Ideal 7 PL can achieve work rates and losses similar to working on level ground, and Chris was delighted with its performance. “It’s very effective, and allowed us to use the power available and maintain high work rates. We were very pleased at how quickly the system re-adjusted after each headland turn which meant little time was wasted.”

Chris said the Ideal’s ability to maintain its performance in a wider range of working conditions than his previous combines will be an advantage in catchy harvests. “We usually start around mid-day when moisture levels have reduced, then work until late evening. The Ideal could work earlier and continue through the night if needed, but most customers prefer harvesting when moisture levels are lower. However, if rain is forecast creating added pressure, then working through the night is an option.”

Dealer relationship

Peacock & Binnington’s back-up has been excellent. “Initial operator training was arranged in France,” explained Andrew. “This would have allowed new operators to take advantage of the earlier harvest there to gain experience in the seat before starting their own crops in the UK. However, Covid-19 restrictions prevented this, so we arranged socially-distanced training in the UK, and made sure that operators could get hold of us throughout harvest if advice was needed.” Chris said his Ideal 7 completed harvest without any breakdowns. Minor repairs and updates were carried out by the dealer team around harvesting schedules to avoid downtime. Daily maintenance was minimal, checks were easily and quickly carried out, and the large fuel tank and efficient engine allowed refuelling every two days.

-moscrop-ideal-1220/MF_Moscrop_Ideal_1220-02-1400x1630.jpg)

Chris Moscrop is impressed by the Ideal’s Vision cab, and said he is always surprised at how quiet it is, even while unloading.

The Moscrop’s Ideal was purchased with a three-year factory warranty, and will be kept for at least five years before being updated. Chris said the simple design means he has no fears regarding reliability. “The Ideal 7 is the right model for our situation and being able to operate it as a self-contained unit towing the header behind has improved the flexibility and efficiency of our contracting business. The combine has plenty of spare capacity, and if we worked in a flatter area then we would probably upgrade to a wider header which would keep the combine full at lower speeds. However, most of last year’s crops were thinner than usual and we still have much to learn about our Ideal 7’s full capabilities.”

-moscrop-ideal-1220/MF_Moscrop_ideal_1220_1400x700.jpg)

-moscrop-ideal-1220/MF_Moscrop_Ideal_1220-01-1400x1004.jpg)

Share

https://www.masseyferguson.com/en_ie/discover-mf/testimonials/moscrop-ideal-1220.html