Tractors

MF 9S

MF 8700 S

MF 8S

MF 7S

MF 6S

MF 5M

MF 5S

MF 5700 M

MF 4700 M

MF 3

MF 1700 M

MF 1700 E

MF 1500

Combine Harvesters

MF IDEAL

MF Beta

MF Activa S

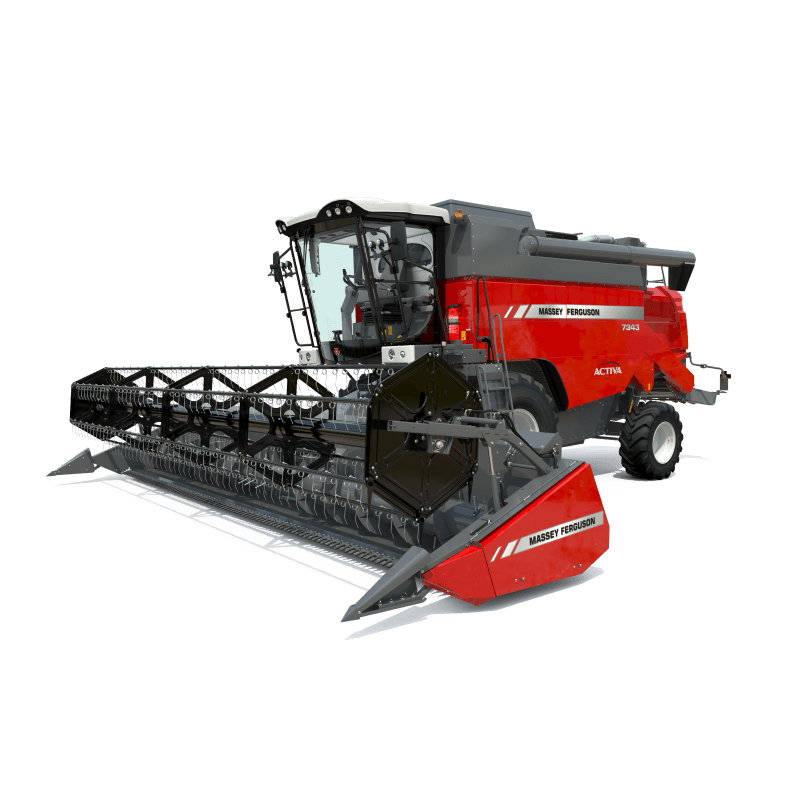

MF Activa

Balers

MF 1840

MF 1842S

MF 2200

MF RB F

MF RB F PROTEC

MF RB V

MF RB V PROTEC

MF TW

Hay and Forage

MF RK Series

MF DM & M Series

MF TD Series

Materials Handling

MF TH

MF FL

MF FL X

An MF 3710 F (Fruit) tractor is at the heart of a strategy to further mechanise the production of blackcurrants at the 800ha Bradenham Hall Farms in Swaffham, Norfolk.

“Historically, we have planted our blackcurrant cuttings by hand from December to February,” says David Pike, Farm Manager. “Now with the help of the MF 3700 F fitted with GPS RTK auto-steering and equipped with a new mechanised planter, we’re aiming to reduce that planting period from three months to three weeks.”

Bradenham Hall Farms has been growing blackcurrants since 1952 and is one of the country’s biggest producers. Today, it has 130ha under production and this year’s yield totalled 450 tonnes. The entire harvest goes to Ribena to make its famous soft drink (as does, incidentally, 90% of Britain’s blackcurrant crop.)

“Blackcurrants have a reputation as one of the easiest crops to grow but they are very time-consuming. Every day of the year at least one or two people are doing something that’s blackcurrant-related here!” David remarks.

The 110hp MF 3710 F tractor, delivered at the end of 2018, is part of a policy to renew and expand Bradenham Hall’s existing machinery fleet and reduce the reliance on casual labour.

“I’ve always found our local MF dealer TNS very helpful and we talked over what we wanted with them,” comments David. “We tried the MF 3710 tractor, liked it and bought it.”

The farm’s 1.5m-wide model comes with MF’s ‘Efficient’ package featuring a 24/12 Power Shuttle transmission, up to 120 litres/min hydraulic flow with two rear electronic spool valves, a mid-mounted spool valve plus an electronic rear linkage and electronic linkage levelling. David also opted for fully-integrated factory–fitted front linkage and PTO.

Along with the soon-to-arrive planter plus another new piece of kit – a mechanised scythe - the MF 3710 works with a front-mounted finishing mower, a topper and a fertiliser spreader.

The blackcurrant bushes are planted 30cm apart with 3m between the rows. “Grass is grown in the alleys to encourage beneficial insects (for example to eat vine weevils) and to absorb moisture and, thus, create a drier surface for the machinery and workforce,” explains David. “The tractor cuts this grass around half a dozen times a year with the vari-width mower.”

Bradenham Hall is highly-committed to countryside stewardship and the MF 3710 F is used with the 3m topper to manage the 8-metre margins around the blackcurrant fields before the hedges are trimmed.

“The tractor is easy to use and operator-friendly especially with its electronic controls. The spool valve finger switches are handy and the shuttle lever is very smooth for moving between forward and reverse,” David adds. “The fact that the driver can disengage the drive and change gear without having to use the clutch makes things a lot easier. It means less effort and is less tiring. The cab is good and you can happily sit in it all day. It’s got great visibility too and we like the air-con and radio.”

Transmission controls on the MF 3700 Series are situated on the gear lever allowing the operator to select neutral/forward/reverse and high/low on one lever for improved control. The driver can take advantage of eight clutchless ratio per range. The 24/12 Powershuttle version has a unique joystick-mounted transmission button which groups clutch, transmission and implement function into one easy control.

“As well as carrying out our traditional tractor jobs, the MF 3710 F is going to take on a lot of our hand work,” David sums up. “Equipped with the new planter and GPS auto-steering, we’ll be able to create an accurate line when establishing the blackcurrant bushes and use that as the foundation for all our mechanised work. We’re looking forward to the arrival of the new implements and transforming the way we do things.”

Share

https://www.masseyferguson.com/en_ie/discover-mf/testimonials/david-pike.html