Tractors

MF 9S

MF 8700 S

MF 8S

MF 7S

MF 6S

MF 5M

MF 5S

MF 5700 M

MF 4700 M

MF 3

MF 1700 M

MF 1700 E

MF 1500

Combine Harvesters

MF IDEAL

MF Beta

MF Activa S

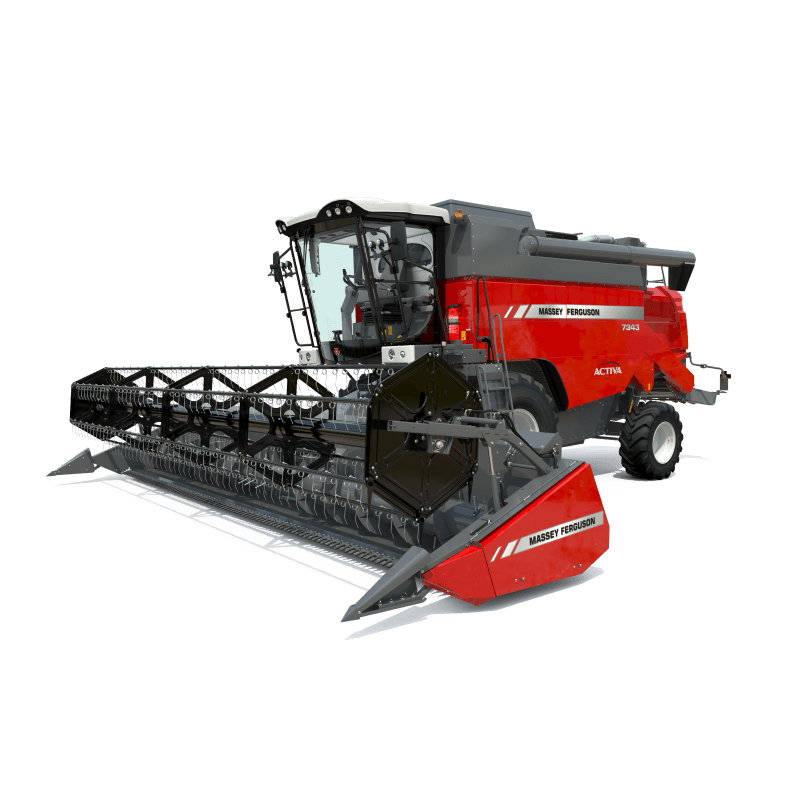

MF Activa

Balers

MF 1840

MF 1842S

MF 2200

MF RB F

MF RB F PROTEC

MF RB V

MF RB V PROTEC

MF TW

Hay and Forage

MF RK Series

MF DM & M Series

MF TD Series

Materials Handling

NEW MF TH

MF FL

MF FL X

The two Massey Ferguson balers bought in 2018 for West Farm, just outside the village of Great Hockham in Norfolk, had great expectations awaiting them.

Each of them was destined to produce between 8,000 and 10,000 straw bales a year, without a hitch, and that's exactly what they achieved in their first summer of work.

West Farm is a family concern, run by the Beards, extending to around 300 acres, growing oilseed rape and winter wheat, together with some fodder beet for the small herd of red poll cattle. The local soils are easy working light, sandy loams, typical of the Breckland area.

Not too demanding, you may think, until, that is, it becomes apparent that the farm's main business is finishing 40,000 pigs on contract for the Tulip food group annually.

The pig enterprise employs 18 full-time staff, but much of the arable work is carried out by Alex Beard, including some contracting, such as carting onions and potatoes for a neighbouring farm and straw for muck. Over the past few seasons, Alex reports, they had increasingly experienced faults and niggles with their existing fleet of balers (not MF!)

“We had heard locally that the Massey balers were pretty useful,” he recalls, “and as we've got a branch of TNS (Thurlow Nunn Standen) just up the road at Attleborough, we thought it might be a good idea to find out a bit more. So we had a chat with their sales guy, young Jolly Bullen, who turned out to be very helpful. In fact, we've come to realise since that he will go out of his way to help, which is not always the case generally.

The Beards soon made the decision to go for two new machines initially – a MF 2240 and a 2270XD. “We particularly like the double knotting system, which has been beefed up create higher density bales, the chain drive principle and their consistency of operation. The whole system has been well tried and tested,” Alex states.

The XD denotes 'extra density', with this model producing bales that are between 15 and 20 per cent more material per bale, so lowering the cost of transport and the storage requirement.

These compelling reasons have convinced him of the merits of ordering another two new MF machines from TNS. “Our two remaining non-MF balers have been giving us a few big needle problems, so little point now in holding back on replacing them. Having all the machines from the same manufacturer makes it easier for the operators to hop from one to another.

“There's another reason for going back to TNS – there's very knowledgeable guy on balers, Steve King, who's been on the service side there for years and it's good to know that he's on the end of a phone if ever we need him. In addition, they keep a very comprehensive stock of parts at the depot.”

Share

https://www.masseyferguson.com/en_ie/discover-mf/testimonials/alex-beard.html