Company Production Director, Tom Theobald with his Massey Ferguson 6S.155 fitted with a Christmas Tree harvesting rig.

A quarter of a million UK homes will enjoy Christmas trees planted, looked after and harvested using two Massey Ferguson tractors which form the backbone of a fleet operated by a Leicestershire-based grower.

The Massey Ferguson MF 7718 S Dyna-6 Efficient and a MF 6S.155 Dyna-VT Exclusive belong to Cadeby Tree Trust, a family-owned business which specialises in quality UK-grown Christmas trees – most of which are supplied through outlets including nurseries and farm shops. “Of approximately 250,000 trees we produce each year, only a small number are sold direct by us to the public,” explained Production Director, Tom Theobald. “The vast majority are supplied to regular trade buyers for resale, and these tend to be outlets where customers want to see the trees unwrapped and check the shape and appearance rather than just buying pre-wrapped trees by size and which are hidden from view.”

Trees are grown on a 10-year cycle on approximately 250ha of land owned by the Theobald family in and around Cadeby, and on rented land in Wales. Approximately 80% are non-needle drop varieties including Nordmann Fir, Noble Fir and Fraser Fir. Traditional Norway Spruce and Blue Spruce trees are also grown although demand for these is reducing.

Before growing Christmas trees, the Cadeby site was a mixed farm owned by Tom’s grandparents. Hay and straw bales were sold and transported to farmers in Wales and, rather than returning empty, lorries were loaded with Christmas trees which were brought back to the farm to be sold. As demand grew, the thriving business developed and replaced the traditional farming activities.

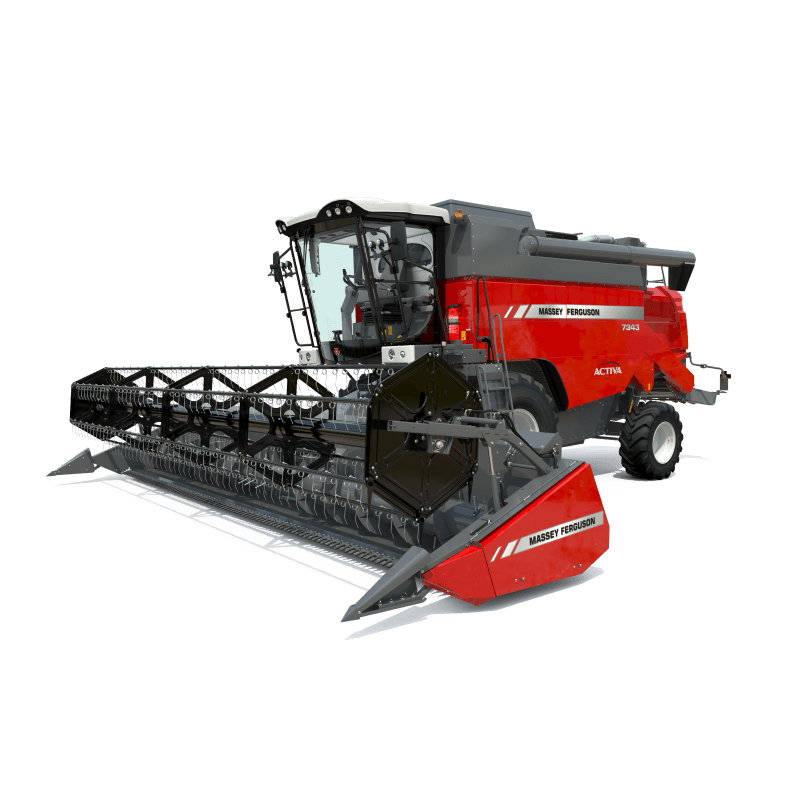

The MF6S.155 Dyna-VT Exclusive was chosen by Leicestershire-based Cadeby Tree Trust for its sizeable Christmas Tree enterprise.

Specialist contracting

As well as growing and looking after its own trees, the company provides a Christmas tree contract-farming service to growers - mainly across central and eastern England. After preparing the ground, three-year old saplings are transplanted, then these are maintained by trimming, and controlling the weeds until the trees are big enough to harvest. Specialist machinery is required, which is why the service offered by Cadeby Tree Trust is so popular with other growers.

Ideal for the task

The Massey Ferguson tractors were chosen for their performance, reliability and manoeuvrability, as well as for the back-up from local dealer, Chandlers (MF) Ltd. “Although most people think of Christmas trees as a seasonal business, the two tractors we own each work approximately 1,000 hours per year,” continued Tom. “In January, work starts clearing fields where trees have been harvested - grinding roots and stumps, and mulching remaining vegetation. Then the land is subsoiled if needed, ploughed or cultivated, then saplings are transplanted using a tractor-mounted planter. The tractor’s GPS guidance ensures straight rows and even row spacing for ease of maintenance. During spring and summer, the trees are trimmed, fertiliser is applied, and weeds are controlled using specialist sprayers.”

Tom said planned investment in new GPS-controlled planters will reduce dependence on chemical weed control. “As well as planting trees in straight lines, the new planters can automatically position each sapling to create diagonal rows across the plantations. This means that tractors with mowers or weed hoes can travel both along and across the rows, avoiding unworked areas between the trees. The Massey Ferguson tractors come with full precision farming capabilities, and we subscribe to an RTK correction signal provided by the Chandlers network. This gives us the accuracy needed for complex field tasks such as operating these new planters.”

Tom Theobald (left) with the Chandlers Agricultural Sales Representative, Anthony Cullum.

MF cab shape ideal

During the short but busy harvesting season, 10–12 additional tractors as well as a fleet of six telehandlers are hired in to operate alongside the farm’s own Massey Ferguson tractors. Specialist harvesting rigs are attached, which each net-wrap up to 1,100 trees per day. Trees are loaded on to a low-level conveyor at the front of the tractor by harvesting teams, then they are wrapped and carried on the belt past the side of the cab and stacked on a rear-mounted pallet platform before being transferred onto trailers for transport to the base.

The Massey Ferguson cab design is ideal, as it is large and comfortable for year-around work making the tractors popular with operators, but there is still space above the left-hand mudguard for the harvesting conveyor and frame. The tractors remain narrow enough to operate in confined areas and can be driven between sites with the harvesting rigs mounted on the road. “They also have a ‘proper door’ on the right-hand side for easy access,” added Tom.

Dyna-VT advantages

The Massey Ferguson 7718 S was supplied by Chandlers five years ago. The 6S.155 is a Dyna-VT model with infinitely variable transmission which was purchased earlier this year. “Both tractors are capable of 50kph which is an advantage when working long distances from the base,” said Tom. “The Dyna-6 powershift gearbox is flexible and easy to use, but we quickly found the Dyna-VT version to be even better.

“Being able to adjust the travel speed precisely to suit the working conditions such as when we are mulching means we obtain maximum performance from the tractor, and for PTO tasks such as spraying or spreading we can maintain a constant engine and PTO speed to suit the implement, while adjusting the travel speed to suit the conditions or compensate for wheel slip on slopes or soft ground. It’s smoother and easier to operate, especially when manoeuvring in tight spaces.”

Operator view

“Both Massey Ferguson tractors perform well, but the newer model is more comfortable on the road and more agile in the field,” commented operator David Cumbley. “We use several hydraulic-driven implements and because the new 6S.155 has a maximum pump capacity of 190 litres/min, this means that most of the time we can obtain the flow we need at very low engine revs. That makes it quieter, especially for those working around it in the field during harvesting, and it saves fuel.”

Experienced Cadeby Tree Trust tractor operator, David Cumbley says that with up to 190 litres/min maximum hydraulic oil flow available, the latest Massey Ferguson 6S.155 can operate many hydraulic-driven implements at very low engine revs, reducing noise levels and fuel consumption.

Standard telematics

“The MF 6S-series is extremely popular with our customers,” added Chandlers Agricultural Sales Representative, Anthony Cullum. “The Dyna-VT transmission selected by Cadeby Tree Trust adds to the versatility and ease of use, and the standard high specification makes the tractors suitable for a wide range of applications.

“MF-Connect telematics come as standard, and I know that Tom finds the MF-Connect smartphone app very useful for monitoring task progress and the tractor’s location. Our engineers also have access to monitor service requirements, and for remote fault diagnosis if issues occur. This helps avoid downtime during busy periods such as during the tree harvesting season.”

The ideal package

“We need reliable tractors with adequate power and performance for our range of specialised implements, but which are compact and manoeuvrable for efficient operation in and round close-spaced trees,” concluded Tom. “As well as our full-time staff, we also employ casual workers during the harvesting season, and it doesn’t take long for them to get used to the straightforward Massey Ferguson controls.

“In our experience, Massey Ferguson tractors are dependable and suffer few problems, but we have a great relationship with the Chandlers team and know that back-up is available whenever it’s needed.”

Share

https://www.masseyferguson.com/en_ie/discover-mf/testimonials/Cadeby-Christmas-Trees.html